Finite Element Models

July 17, 2024

Contents

-

1 Finite Element Models

- 1.1 Overview

- 1.2 FEM model creation

- 1.3 FEM Geometry

-

1.4 Connecting FEM models to other components

- 1.4.1 Connecting nodes to rigid bodies or particles

- 1.4.2 Example: connecting a beam to a block

- 1.4.3 Connecting nodes directly to elements

- 1.4.4 Example: connecting two FEMs together

- 1.4.5 Finding which nodes to attach

- 1.4.6 Selecting nodes in the viewer

- 1.4.7 Example: two bodies connected by an FEM “spring”

- 1.4.8 Nodal-based attachments

- 1.4.9 Example: element vs. nodal-based attachments

- 1.5 FEM markers

- 1.6 Frame attachments

- 1.7 Incompressibility

- 1.8 Varying and augmenting material behaviors

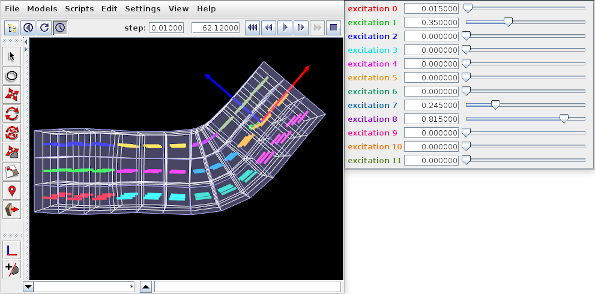

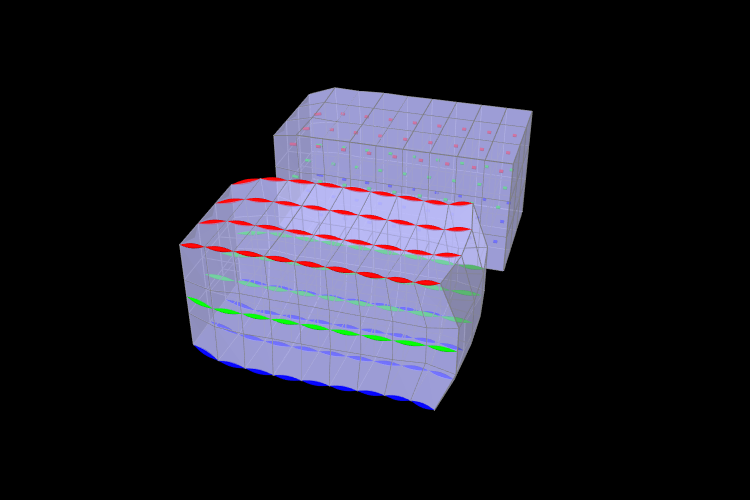

- 1.9 Muscle activated FEM models

-

1.10 Material types

- 1.10.1 Linear

-

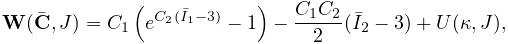

1.10.2 Hyperelastic materials

- 1.10.2.1 St Venant-Kirchoff material

- 1.10.2.2 Neo-Hookean material

- 1.10.2.3 Incompressible neo-Hookean material

- 1.10.2.4 Mooney-Rivlin material

- 1.10.2.5 Ogden material

- 1.10.2.6 Fung orthotropic material

- 1.10.2.7 Yeoh material

- 1.10.2.8 Arruda-Boyce material

- 1.10.2.9 Veronda-Westmann material

- 1.10.2.10 Incompressible material

- 1.10.3 Muscle materials

- 1.11 Stress, strain and strain energy

- 1.12 Rendering and Visualizations

Chapter 1 Finite Element Models

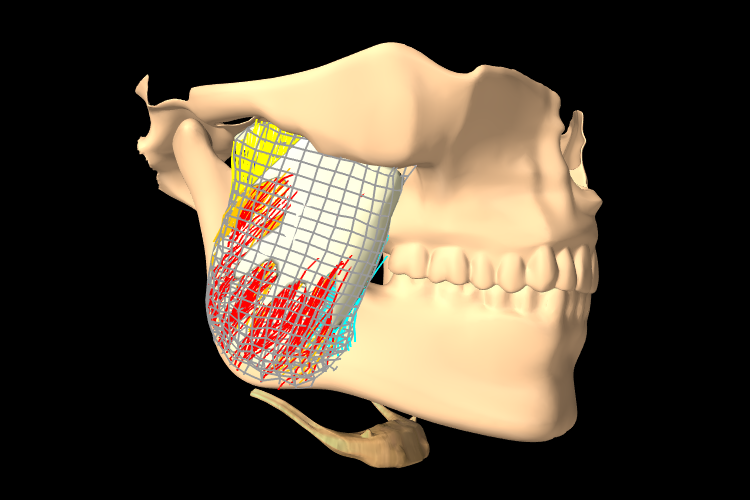

This chapter details how to construct three-dimensional finite element models, and how to couple them with the other simulation components described in previous sections (e.g. particles and rigid bodies). Finite element muscles, which have additional properties that allow them to contract given activation signals, are discussed in Section 1.9. An example FEM model of the masseter, coupled to a rigid jaw and maxilla, is shown in Figure 1.1.

1.1 Overview

The finite element method (FEM) is a numerical technique used for solving a system of partial differential equations (PDEs) over some domain. The general approach is to divide the domain into a set of building blocks, referred to as elements. These partition the space, and form local domains over which the system of equations can be locally approximated. The corners of these elements, the nodes, become control points in a discretized system. The solution is then assumed to be smoothly interpolated across the elements based on values determined at the nodes. Using this discretization, the differential system is converted into an algebraic one, which is often linearized and solved iteratively.

In ArtiSynth, the PDEs considered are the governing equations of continuum mechanics: the conservation of mass, momentum, and energy. To complete the system, a constitutive equation is required that describes the stress-strain response of the material. This constitutive equation is what distinguishes between material types. The domain is the three-dimensional space that the model occupies. This must be divided into small elements which accurately represent the geometry. Within each element, the PDEs are sampled at a set of points, referred to as integration points, and terms are numerically integrated to form an algebraic system to solve.

The purpose of the rest of this chapter is to describe the construction and use of finite elements models within ArtiSynth. It does not further discuss the mathematical framework or theory. For an in-depth coverage of the nonlinear finite element method, as applied to continuum mechanics, the reader is referred to the textbook by Bonet and Wood [bonet:fem:2000].

1.1.1 FemModel3d

The basic type of finite element model is implemented in the class FemModel3d. This class controls some properties that are used by the model as a whole. The key ones that affect simulation dynamics are:

| Property | Description |

|---|---|

| density | The density of the model |

| material | An object that describes the material’s constitutive law (i.e. its stress-strain relationship). |

| particleDamping | Proportional damping associated with the particle-like motion of the FEM nodes. |

| stiffnessDamping | Proportional damping associated with the system’s stiffness term. |

These properties can be set and retrieved using the methods

| void setDensity (double density) |

Sets the density. |

| double getDensity() |

Gets the density. |

| void setMaterial (FemMaterial mat) |

Sets the FEM’s material. |

| FemMaterial getMaterial() |

Gets the FEM’s material. |

| void setParticleDamping (double d) |

Sets the particle (mass) damping. |

| double getParticleDamping() |

Gets the particle (mass) damping. |

| void setStiffnessDamping (double d) |

Sets the stiffness damping. |

| double getStiffnessDamping() |

Gets the stiffness damping. |

Keep in mind that ArtiSynth is essentially “unitless” (Section LABEL:sec:mechii:units), so it is the responsibility of the developer to ensure that all properties are specified in a compatible way.

The density of the model is used to compute the mass distribution throughout the volume. Note that we use a diagonally lumped mass matrix (DLMM) formulation, so the mass is assumed to be concentrated at the location of the discretized FEM nodes. To allow for a spatially-varying density, densities can be explicitly set for individual elements, or masses can be explicitly set for individual nodes.

The FEM’s material property is a delegate object used to compute stress and stiffness within individual elements. It handles the constitutive component of the model, as described in more detail in Sections 1.1.3 and 1.10. In addition to the main material defined for the model, it is also possible set a material on a per-element basis, and to define additional materials which augment the behavior of the main materials (Section 1.8).

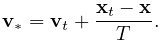

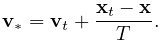

The two damping parameters are related to Rayleigh damping, which is used to dissipate energy within finite element models. There are two proportional damping terms: one related to the system’s mass, and one related to stiffness. The resulting damping force applied is

| (1.1) |

where ![]() is the value of particleDamping,

is the value of particleDamping, ![]() is the value of

stiffnessDamping,

is the value of

stiffnessDamping, ![]() is the FEM model’s lumped mass matrix,

is the FEM model’s lumped mass matrix, ![]() is

the FEM’s stiffness matrix, and

is

the FEM’s stiffness matrix, and ![]() is the concatenated vector of FEM node

velocities. Since the lumped mass matrix is diagonal, the mass-related

component of damping can be applied separately to each FEM node. Thus, the

mass component reduces to the same system as Equation (LABEL:eqn:pointdamping),

which is why it is referred to as “particle damping”.

is the concatenated vector of FEM node

velocities. Since the lumped mass matrix is diagonal, the mass-related

component of damping can be applied separately to each FEM node. Thus, the

mass component reduces to the same system as Equation (LABEL:eqn:pointdamping),

which is why it is referred to as “particle damping”.

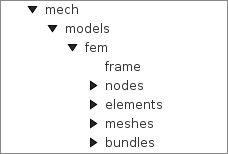

1.1.2 Component Structure

Each FemModel3d contains several lists of subcomponents:

- nodes

-

The particle-like dynamic components of the model. These lie at the corners of the elements and carry all the mass (due to DLMM formulation).

- elements

-

The volumetric model elements. These define the 3D sub-units over which the system is numerically integrated.

- shellElements

-

The shell elements. These define additional 2D sub-units over which the system is numerically integrated.

- meshes

-

The geometry in the model. This includes the surface mesh, and any other embedded geometries.

- materials

-

Optional additional materials which can be added to the model to augment the behavior of the model’s material property. This is described in more detail in Section 1.8.

- fields

-

Optional field components which can be used to interpolate application-defined quantities over the FEM model’s domain. Fields are described in detail in Chapter LABEL:sec:fields.

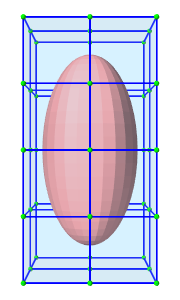

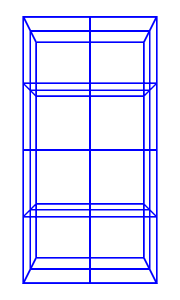

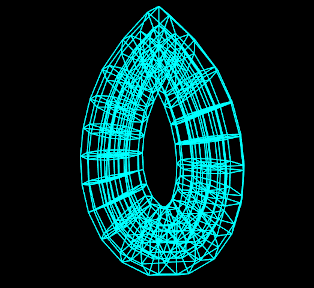

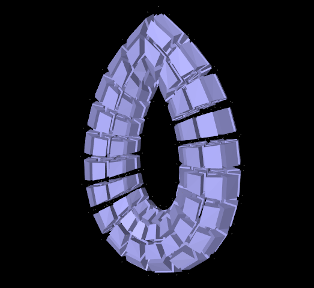

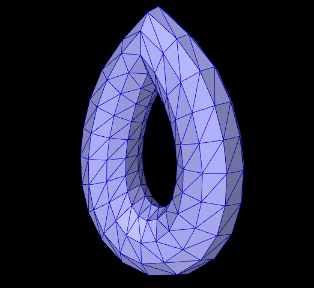

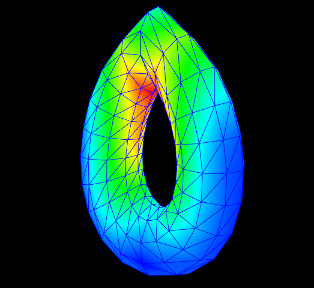

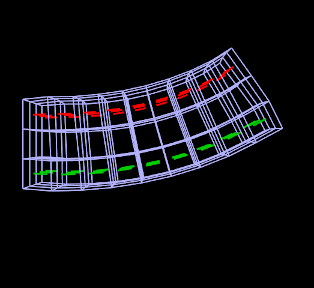

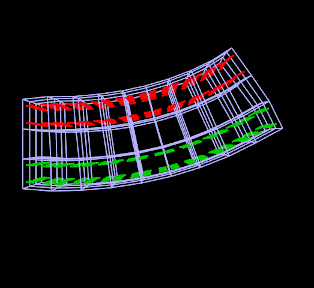

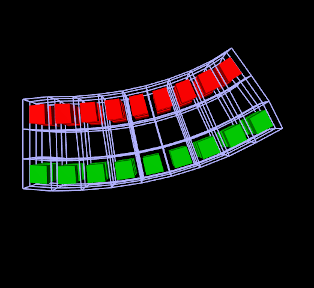

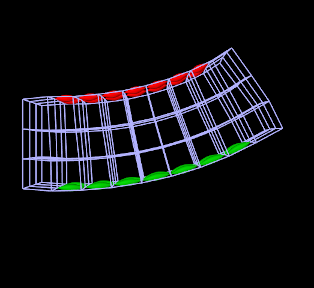

The nodes, elements and meshes components are illustrated in Figure 1.2.

|

|

|

|

| (a) FEM model | (b) Nodes | (c) Elements | (d) Geometry |

1.1.2.1 Nodes

The set of nodes belong to a finite element model can be obtained by the method

| PointList<FemNode3d> getNodes() |

Returns the list of FEM nodes. |

Nodes are implemented in the class FemNode3d, which is a subclass of Particle (Section LABEL:ParticlesAndSprings:sec). They are the main dynamic components of the finite element model. The key properties affecting simulation dynamics are:

| Property | Description |

|---|---|

| restPosition | The initial position of the node. |

| position | The current position of the node. |

| velocity | The current velocity of the node. |

| mass | The mass of the node. |

| dynamic | Whether the node is considered dynamic or parametric (e.g. boundary condition). |

Each of these properties has corresponding getXxx() and setXxx(...) functions to access and modify them.

The restPosition property defines the node’s position in the FEM model’s “natural” or “undeformed” state. Rest positions are used to compute an initial configuration for the model, from which strains are determined. A node’s rest position can be updated in code using the method: FemNode3d.setRestPosition(Point3d).

If any node’s rest positions are changed, the current values for stress and stiffness will become invalid. They can be manually updated using the method FemModel3d.updateStressAndStiffness() for the parent model. Otherwise, stress and stiffness will be automatically updated at the beginning of the next time step.

The properties position and velocity give the node’s current 3D state. These are common to all point-like particles, as is the mass property. Here, however, mass represents the lumped mass of the immediately surrounding material. Its value is initialized by equally dividing mass contributions from each adjacent element, given their densities. For a finer control of spatially-varying density, node masses can be set manually after FEM creation.

The FEM node’s dynamic property specifies whether or not the node is considered when computing the dynamics of the system. If not, it is treated as being parametrically controlled. This has implications when setting boundary conditions (Section 1.1.4).

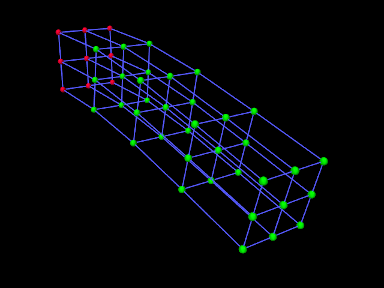

1.1.2.2 Elements

Elements are the 3D volumetric spatial building blocks of the domain. Within each element, the displacement (or strain) field is interpolated from displacements at nodes:

|

(1.2) |

where ![]() is the displacement of the

is the displacement of the ![]() th node that is adjacent to the

element, and

th node that is adjacent to the

element, and ![]() is referred to as the shape function (or

basis function) associated with that node. Elements are classified by

their shape, number of nodes, and shape function order (Table

1.1). ArtiSynth supports the following element types,

shown below with their node numberings:

is referred to as the shape function (or

basis function) associated with that node. Elements are classified by

their shape, number of nodes, and shape function order (Table

1.1). ArtiSynth supports the following element types,

shown below with their node numberings:

| TetElement | PyramidElement | WedgeElement | HexElement |

| QuadtetElement | QuadpyramidElement | QuadwedgeElement | QuadhexElement |

| Element Type | # Nodes | Order | # Integration Points |

|---|---|---|---|

| TetElement | 4 | linear | 1 |

| PyramidElement | 5 | linear | 5 |

| WedgeElement | 6 | linear | 6 |

| HexElement | 8 | linear | 8 |

| QuadtetElement | 10 | quadratic | 4 |

| QuadpyramidElement | 13 | quadratic | 5 |

| QuadwedgeElement | 15 | quadratic | 9 |

| QuadhexElement | 20 | quadratic | 14 |

The base class for all of these is FemElement3d. A numerical integration is performed within each element to create the (tangent) stiffness matrix. This integration is performed by evaluating the stress and stiffness at a set of integration points within each element, and applying numerical quadrature. The list of elements in a model can be obtained with the method

| RenderableComponentList<FemElement3d> getElements() |

Returns the list of volumetric elements. |

All objects of type FemElement3d have the following properties:

| Property | Description |

|---|---|

| density | Density of the element |

| material | An object that describes the constitutive law within the element (i.e. its stress-strain relationship). |

If left unspecified, the element’s density is inherited from the containing FemModel3d object. When set, the mass of the element is computed and divided amongst all its nodes, updating the lumped mass matrix.

1.1.2.3 Shell elements

Shell elements are additional 2D spatial building blocks which can be added to a model. They are typically used to model structures which are too thin to be easily represented by 3D volumetric elements, or to provide additional internal stiffness within a set of volumetric elements.

ArtiSynth presently supports the following shell element types, with the number of nodes, shape function order, and integration point count described in Table 1.2:

| Element Type | # Nodes | Order | # Integration Points |

|---|---|---|---|

| ShellTriElement | 3 | linear | 9 (3 if membrane) |

| ShellQuadElement | 4 | linear | 8 (4 if membrane) |

The base class for all shell elements is ShellElement3d, which contains the same density and material properties as FemElement3d, as well as the additional property defaultThickness, whose use will be described below.

The list of shell elements in a model can be obtained with the method

| RenderableComponentList<ShellElement3d> getShellElements() |

Returns the list of shell elements. |

Both the volumetric elements (FemElement3d) and the shell elements (ShellElement3d) derive from the base class FemElement3dBase. To obtain all the elements in an FEM model, both shell and volumetric, one may use the method

| ArrayList<FemElement3dBase> getAllElements() |

Returns a list of all elements. |

Each shell element can actually be instantiated in two forms:

-

•

As a regular shell element, which has a bending stiffness;

-

•

As a membrane element, which does not have bending stiffness.

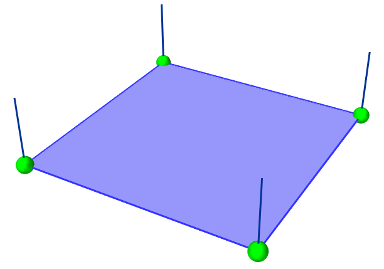

Regular shell elements are implemented using the same extensible director formulation used by FEBio [MaasFEBio2012], and more specifically the front/back node formulation [FEBioTheory2018]. Each node associated with a (regular) shell element is assigned a director, which is a 3D vector providing a normal direction and virtual thickness at that node (Figure 1.3). This virtual thickness allows us to continue to use 3D materials to provide the constitutive laws that determine the shell’s stress/strain response, including its bending behavior. It also allows us to continue to use the element’s density to determine its mass.

Director information is automatically assigned to a FemNode3d whenever one or more regular shell elements is connected to it. This information includes both the current value of the director, its rest value, and its velocity, with the difference between the first two determining the element’s bending strain. These quantities can be queried using the methods

For nodes which are not connected to regular shell elements, and therefore do not have director information assigned, these methods all return a zero-valued vector.

If not otherwise specified, the current and rest director values are

computed automatically from the surrounding (regular) shell elements,

with their value ![]() being computed from

being computed from

where ![]() is the value of the defaultThickness property and

is the value of the defaultThickness property and

![]() is the surface normal of the

is the surface normal of the ![]() -th surrounding regular shell

element.

However, if necessary, it is also possible to explicitly assign

these values, using the methods

-th surrounding regular shell

element.

However, if necessary, it is also possible to explicitly assign

these values, using the methods

ArtiSynth FEM nodes can currently support only one director, which is shared by all regular shell elements associated with that node. This effectively means that all such elements must belong to the same “surface”, and that two intersecting surfaces cannot share the same nodes.

As indicated above, shell elements can also be instantiated as membrane elements, which do not exhibit bending stiffness and therefore do not require director information. The regular/membrane distinction is specified in the element’s constructor. For example, ShellTriElement and ShellQuadElement each have constructors with the signatures:

The thickness argument specifies the defaultThickness property, while membrane determines whether or not the element is a membrane element.

While membrane elements do not require explicit director information stored at the nodes, they do make use of an inferred director that is parallel to the element’s surface normal, and has a constant length equal to the element’s defaultThickness property. This gives the element a virtual volume, which (as with regular elements) is used to determine 3D strains and to compute the element’s mass from it’s density.

1.1.2.4 Meshes

The geometry associated with a finite element model consists of a collection of meshes (e.g. PolygonalMesh, PolylineMesh, PointMesh) that move along with the model in a way that maintains the shape function interpolation equation (1.2) at each vertex location. These geometries can be used for visualizations, or for physical interactions like collisions. However, they have no physical properties themselves. FEM geometries will be discussed in more detail in Section 1.3. The list of meshes can be obtained with the method

1.1.3 Materials

The stress-strain relationship within each element is defined by a “material” delegate object, implemented by a subclass of FemMaterial. This material object is responsible for implementing the functions

which computes the stress tensor and (optionally) the tangent stiffness matrix at each integration point, based on the current local deformation at that point.

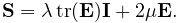

All supported materials are presented in detail in Section

1.10. The default material type is

LinearMaterial, which

linearly maps Cauchy strain ![]() onto Cauchy stress

onto Cauchy stress ![]() via

via

where ![]() is the elasticity tensor determined

from Young’s modulus and Poisson’s ratio. Anisotropic

linear materials are provided by

TransverseLinearMaterial

and

AnisotropicLinearMaterial.

Linear materials in ArtiSynth implement corotation, which removes the

rotation from the deformation gradient and allows Cauchy strain to be

applied to large

deformations [ngan:fem:2008, muller2004interactive]. Nonlinear

hyperelastic materials are also supported, including

MooneyRivlinMaterial,

OgdenMaterial,

YeohMaterial,

ArrudaBoyceMaterial,

and

VerondaWestmannMaterial.

is the elasticity tensor determined

from Young’s modulus and Poisson’s ratio. Anisotropic

linear materials are provided by

TransverseLinearMaterial

and

AnisotropicLinearMaterial.

Linear materials in ArtiSynth implement corotation, which removes the

rotation from the deformation gradient and allows Cauchy strain to be

applied to large

deformations [ngan:fem:2008, muller2004interactive]. Nonlinear

hyperelastic materials are also supported, including

MooneyRivlinMaterial,

OgdenMaterial,

YeohMaterial,

ArrudaBoyceMaterial,

and

VerondaWestmannMaterial.

1.1.4 Boundary conditions

Boundary conditions can be implemented in one of several ways:

-

1.

Explicitly setting FEM node positions/velocities

-

2.

Attaching FEM nodes to other dynamic components

-

3.

Enabling collisions

To enforce an explicit (Dirichlet) boundary condition for a set of nodes, their dynamic property must be set to false. This notifies ArtiSynth that the state of these nodes (both position and velocity) will be controlled parametrically. By disabling dynamics, a fixed boundary condition is applied. For a moving boundary, positions and velocities of the boundary nodes must be explicitly set every timestep. This can be accomplished with either a Controller (see Section LABEL:ControllersAndMonitors:sec) or an InputProbe (see Section LABEL:Probes:sec). Note that both the position and velocity of the nodes should be explicitly set for consistency.

Another type of supported boundary condition is to attach FEM nodes to other components, including particles, springs, rigid bodies, and locations within other FEM elements. Here, the node is still considered dynamic, but its motion is coupled to that of the attached component through a constraint mechanism. Attachments will be discussed further in Section 1.4.

Finally, the boundary of an FEM can be constrained by enabling collisions with other components. This will be covered in Chapter LABEL:ContactAndCollision:sec.

1.2 FEM model creation

Creating a finite element model in ArtiSynth typically follows the pattern:

The main code block for the FEM setup should do the following:

-

•

Build the node/element structure

-

•

Set physical properties

-

–

density

-

–

damping

-

–

material

-

–

-

•

Set boundary conditions

-

•

Set render properties

Building the FEM structure can be done with the use of factory methods for simple shapes, by loading external files, or by writing code to manually assemble the nodes and elements.

1.2.1 Factory methods

For simple shapes such as beams and ellipsoids, there are factory methods to automatically build the node and element structure. These methods are found in the FemFactory class. Some common methods are

The inputs specify the dimensions, resolution, and potentially the type of element to use. The following code creates a basic beam made up of hexahedral elements:

1.2.2 Loading external FEM meshes

For more complex geometries, volumetric meshes can be loaded from external files. A list of supported file types is provided in Table 1.3. To load a geometry, an appropriate file reader must be created. Readers capable of reading FEM models implement the interface FemReader, which has the method

Additionally, many FemReader classes have static methods to handle the loading of files for convenience.

| Format | File extensions | Reader | Writer |

|---|---|---|---|

| ANSYS | .node, .elem | AnsysReader | AnsysWriter |

| TetGen | .node, .ele | TetGenReader | TetGenWriter |

| Abaqus | .inp | AbaqusReader | AbaqusWriter |

| VTK (ASCII) | .vtk | VtkAsciiReader | – |

The following code snippet demonstrates how to load a model using the AnsysReader.

The method PathFinder.getSourceRelativePath() is used to find a path within the ArtiSynth source tree that is relative to the current model’s source file (Section LABEL:PathFinder:sec). Note the try-catch block. Most of these readers throw an IOException if the read fails.

1.2.3 Generating from surfaces

There are two ways an FEM model can be generated from a surface: by using a FEM mesh generator, and by extruding a surface along its normal direction.

ArtiSynth has the ability to interface directly with the TetGen library (http://tetgen.org) to create a tetrahedral volumetric mesh given a closed and manifold surface. The main Java class for calling TetGen directly is TetgenTessellator. The tessellator has several advanced options, allowing for the computation of convex hulls, and for adding points to a volumetric mesh. For simply creating an FEM from a surface, there is a convenience routine within FemFactory that handles both mesh generation and constructing a FemModel3d:

If quality ![]() , then points will be added in an attempt to bound the

maximum radius-edge ratio (see the -q switch for TetGen). According

to the TetGen documentation, the algorithm usually succeeds for a

quality ratio of 1.2.

, then points will be added in an attempt to bound the

maximum radius-edge ratio (see the -q switch for TetGen). According

to the TetGen documentation, the algorithm usually succeeds for a

quality ratio of 1.2.

It’s also possible to create thin layer of elements by extruding a surface along its normal direction.

For example, to create a two-layer slice of elements centered about a surface of a tendon mesh, one might use

For this type of extrusion, triangular faces become wedge elements, and quadrilateral faces become hexahedral elements.

Note: for extrusions, no care is taken to ensure element quality; if the surface has a high curvature relative to the total extrusion thickness, then some elements will be inverted.

1.2.4 Building elements in code

A finite element model’s structure can also be manually constructed in code. FemModel3d has the methods:

For an element to successfully be added, all its nodes must already have been added to the model. Nodes can be constructed from a 3D location, and elements from an array of nodes. A convenience routine is available in FemElement3d that automatically creates the appropriate element type given the number of nodes (Table 1.1):

Be aware of node orderings when supplying nodes. For linear elements, ArtiSynth uses a clockwise convention with respect to the outward normal for the first face, followed by the opposite node(s). To determine the correct ordering for a particular element, check the coordinates returned by the function FemElement3dBase.getNodeCoords(). This returns the concatenated coordinate list for an “ideal” element of the given type.

1.2.5 Example: a simple beam model

A complete application model that implements a simple FEM beam is given below.

This example can be found in artisynth.demos.tutorial.FemBeam. The build() method first creates a MechModel and FemModel3d. A FEM beam is created using a factory method on line 36. This beam is centered at the origin, so its length extends from -length/2 to length/2. The density, damping and material properties are then assigned.

On lines 45–49, a fixed boundary condition is set to the left-hand side of the beam by setting the corresponding nodes to be non-dynamic. Due to numerical precision, a small EPSILON buffer is required to ensure all left-hand boundary nodes are identified (line 46).

Rendering properties are then assigned to the FEM model on line 52. These will be discussed further in Section 1.12.

1.3 FEM Geometry

Associated with each FEM model is a list of geometry with the heading meshes. This geometry can be used for either display purposes, or for interactions such as collisions (Section LABEL:CompoundCollidablesAndSelf:sec). A geometry itself has no physical properties; its motion is entirely governed by the FEM model that contains it.

All FEM geometries are of type FemMeshComp, which stores a reference to a mesh object (Section LABEL:Meshes:sec), as well as attachment information that links vertices of the mesh to points within the FEM. The attachments enforce the shape function interpolation in Equation (1.2) to hold at each mesh vertex, with constant shape function coefficients.

1.3.1 Surface meshes

By default, every FemModel3d has an auto-generated geometry representing the “surface mesh”. The surface mesh consists of all un-shared element faces (i.e. the faces of individual elements that are exposed to the world), and its vertices correspond to the nodes that make up those faces. As the FEM nodes move, so do the mesh vertices due to the attachment framework.

The surface mesh can be obtained using one of the following functions in FemModel3d:

The first returns the surface complete with attachment information. The latter method directly returns the PolygonalMesh that is controlled by the FEM.

It is possible to manually set the surface mesh:

However, doing so is normally not necessary. It is always possible to add additional mesh geometries to a finite element model, and the visibility settings can be changed so that the default surface mesh is not rendered.

1.3.2 Embedding geometry within an FEM

Any geometry of type MeshBase can be added to a FemModel3d. To do so, first position the mesh so that its vertices are in the desired locations inside the FEM, then call one of the FemModel3d methods:

The latter is a convenience routine that also gives the newly embedded FemMeshComp a name.

1.3.3 Example: a beam with an embedded sphere

A complete model demonstrating embedding a mesh is given below.

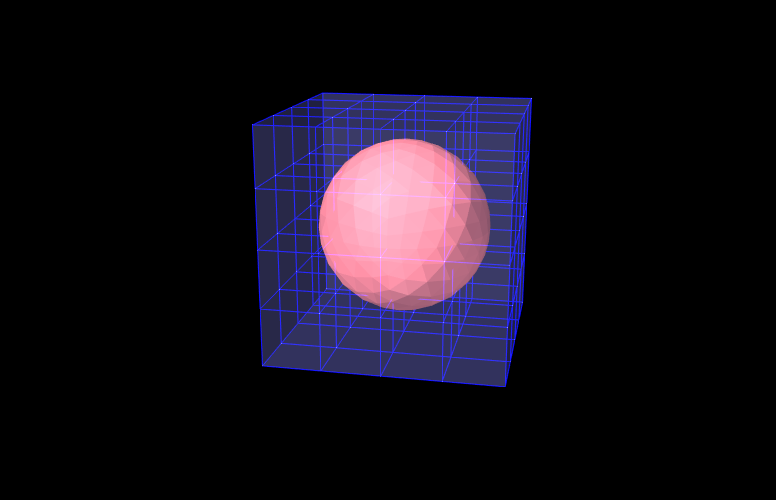

This example can be found in artisynth.demos.tutorial.FemEmbeddedSphere. The model is very similar to FemBeam. A MechModel and FemModel3d are created and added. At line 41, a PolygonalMesh of a sphere is created using a factory method. The sphere is already centered inside the beam, so it does not need to be repositioned. At Line 42, the sphere is embedded inside model fem, creating a FemMeshComp with the name “sphere”. The full model is shown in Figure 1.5.

1.4 Connecting FEM models to other components

To couple FEM models to other dynamic components, the “attachment” mechanism described in Section LABEL:PhysicsSimulation:sec is used. This involves creating and adding to the model attachment components, which are instances of DynamicAttachment, as described in Section LABEL:Attachments:sec. Common point-based attachment classes are listed in Table 1.4.

| Attachment | Description |

|---|---|

| PointParticleAttachment | Attaches one “point” to one “particle” |

| PointFrameAttachment | Attaches one “point” to one “frame” |

| PointFem3dAttachment | Attaches one “point” to a linear combination of FEM nodes |

FEM models are connected to other model components by attaching their nodes to various components. This can be done by creating an attachment object of the appropriate type, and then adding it to the MechModel using

There are also convenience routines inside MechModel that will create the appropriate attachments automatically (see Section LABEL:sec:mech:pointattachments).

All attachments described in this section are based around FEM nodes. However, it is also possible to attach frame-based components (such as rigid bodies) directly to an FEM, as described in Section 1.6.

1.4.1 Connecting nodes to rigid bodies or particles

Since FemNode3d is a subclass of Particle, the same methods described in Section LABEL:sec:mech:pointattachments for attaching particles to other particles and frames are available. For example, we can attach an FEM node to a rigid body using a either a statement of the form

or the following equivalent statement which does the same thing:

Both of these create a PointFrameAttachment between a rigid body (called body) and an FEM node (called node) and then adds it to the MechModel mech.

1.4.2 Example: connecting a beam to a block

The following model demonstrates attaching an FEM beam to a rigid block.

This model extends the FemBeam example of Section 1.2.5. The build() method then creates and adds a RigidBody block (lines 18–20). On line 21, the block is repositioned to the side of the beam to prepare for the attachment. On lines 24–28, all right-most nodes of the beam are then set to be attached to the block using a PointFrameAttachment. In this case, the attachments are explicitly created. They could also have been attached using

1.4.3 Connecting nodes directly to elements

Typically, nodes do not align in a way that makes it

possible to connect them to other FEM models and/or points based on

simple point-to-node attachments. Instead, we use a different

mechanism that allows us to attach a point to an arbitrary location

within an FEM model. This is done using an attachment component of

type

PointFem3dAttachment, which

implements an attachment where the position ![]() and velocity

and velocity ![]() of the

attached point is determined by a weighted sum of the positions

of the

attached point is determined by a weighted sum of the positions ![]() and velocities

and velocities ![]() of selected fem nodes:

of selected fem nodes:

| (1.3) |

Any force ![]() acting on the attached point is then propagated back

to the nodes, according to the relation

acting on the attached point is then propagated back

to the nodes, according to the relation

| (1.4) |

where ![]() is the force acting on node

is the force acting on node ![]() due to

due to ![]() . This

relation can be derived based on the conservation of energy.

If

. This

relation can be derived based on the conservation of energy.

If ![]() is embedded within a single element, then the

is embedded within a single element, then the ![]() are

simply the element nodes and the

are

simply the element nodes and the ![]() are corresponding shape

function values; this is known as an element-based attachment.

On the other hand, as described below, it is sometimes desirable to

form an attachment using a more general set of nodes that extends

beyond a single element; this is known as a nodal-based

attachment (Section 1.4.8).

are corresponding shape

function values; this is known as an element-based attachment.

On the other hand, as described below, it is sometimes desirable to

form an attachment using a more general set of nodes that extends

beyond a single element; this is known as a nodal-based

attachment (Section 1.4.8).

An element-based attachment can be created using a code fragment of the form

First, a PointFem3dAttachment is created for the point pnt. Next, setFromElement() is used to determine the nodal weights within the element elem for the specified position (which in this case is simply the point’s current position). To do this, it computes the “natural coordinates” coordinates of the position within the element. For this to be guaranteed to work, the position should be on or inside the element. If natural coordinates cannot be found, the method will return false and the nearest estimates coordinates will be used instead. However, it is sometimes possible to find natural coordinates outside a given element as long as the shape functions are well-defined. Finally, the attachment is added to the model.

More conveniently, the exact same functionality is provided by the attachPoint() method in MechModel:

This creates an attachment identical to that created by the previous code fragment.

Often, one does not want to have to determine the element to which a point should be attached. In that case, one can call

or, equivalently,

This will find the nearest element to the node in question and use that to create the attachment. If the node is outside the FEM model, then it will be attached to the nearest point on the FEM’s surface.

1.4.4 Example: connecting two FEMs together

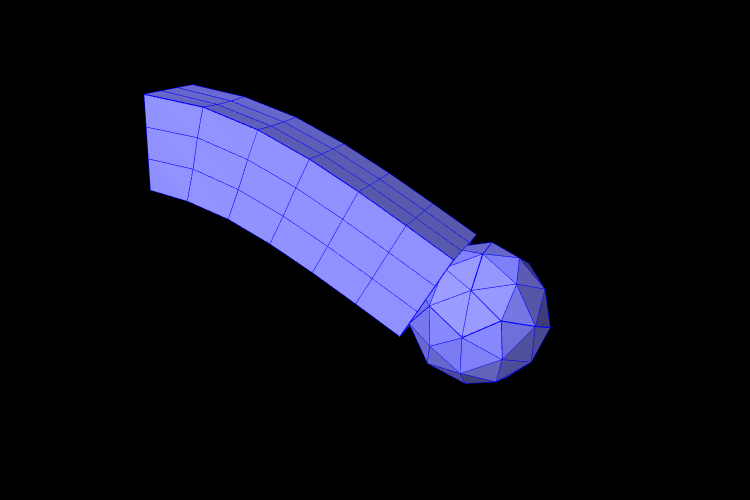

The following model demonstrates how to attach two FEM models together:

This example can be found in artisynth.demos.tutorial.FemBeamWithFemSphere. The model extends FemBeam, adding a finite element sphere and coupling them together. The sphere is created and added on lines 18–28. It is read from TetGen-generated files using the TetGenReader class. The model is then scaled to match the dimensions of the current model, and transformed to the right side of the beam. To create attachments, the code first checks for any nodes that belong to the sphere that fall inside the beam using the FemModel3d.findContainingElement(Point3d) method (line 36), which returns the containing element if the point is inside the model, or null if the point is outside. Internally, this spatial search uses a bounding volume hierarchy for efficiency (see BVTree and BVFeatureQuery). If the point is contained within the beam, then mech.attachPoint() is used to attach it to the nodes of the element (line 39).

1.4.5 Finding which nodes to attach

While it is straightforward to connect nodes to rigid bodies or other FEM nodes or elements, it is often necessary to determine which nodes to attach. This was evident in the example of Section 1.4.4, which attached nodes of an FEM sphere that were found to be inside an FEM beam.

As in that example, finding the nodes to attach can often be done using geometric queries. For example, we often select nodes based on how close they are to the other body we wish to attach to.

Various prolixity queries are available for this task. To find the distance of a point to a polygonal mesh, we can use the following PolygonalMesh methods,

| double distanceToPoint(Point3d pnt) |

Returns the distance of pnt to the mesh. |

| int pointIsInside (Point3d pnt) |

Returns true if pnt is inside the mesh. |

where the latter method returns 1 if the point is inside and 0 otherwise. For checking the distance of an FEM node, pnt can be obtained from node.getPosition() (or possibly node.getRestPosition()). For example, to find all nodes within a distance tol of the surface of a rigid body, we could use the code fragment:

If we want to check only nodes that lie on the FEM surface, then we can filter them using the FemModel3d method isSurfaceNode():

Most of the mesh-based query methods work only for triangular meshes. The PolygonalMesh method isTriangular() can be used to determine if the mesh is triangular. If it is not, it can made triangular by calling triangulate(), although in general this should be done during model construction before the mesh-based component has been added to the model.

For connecting an FEM model to another FEM model, FemModel3d provides a number of query methods:

| Nearest element queries: | |

|---|---|

| FemElement3dBase findNearestElement( MPoint3d near, Point3d pnt) |

Find nearest element (shell or volumetric) to pnt. |

| FemElement3dBase findNearestElement( MPoint3d near, Point3d pnt, ElementFilter filter) |

Find nearest filtered element (shell or volumetric) to pnt. |

| FemElement3dBase findNearestSurfaceElement( MPoint3d near, Point3d pnt) |

Find nearest surface element (shell or volumetric) to pnt. |

| FemElement3d findNearestVolumetricElement ( MPoint3d near, Point3d pnt) |

Find nearest volumetric element to pnt. |

| ShellElement3d findNearestShellElement ( MPoint3d near, Point3d pnt) |

Find nearest shell element to pnt. |

| FemElement3d findContainingElement(Point3d pnt) |

Find volumetric element (if any) containing pnt. |

| Nearest node queries: | |

|---|---|

| FemNode3d findNearestNode ( MPoint3d pnt, double maxDist) |

Find nearest node to pnt that is within maxDist. |

| ArrayList<FemNode3d> findNearestNodes ( MPoint3d pnt, double maxDist) |

Find all nodes that are within maxDist of pnt. |

All the above queries are based on the FEM model’s current nodal

positions. The method

findNearestElement(near,pnt,filter) allows the application to

specify

a FemModel.ElementFilter to

restrict the elements that are searched.

The argument near that appears in some of the queries is an optional argument which, if not null, returns the location of the corresponding nearest point on the element. The distance from pnt to the element can then be found using

near.distance (pnt);

If the resulting distance is 0, then the point is on or inside the element. Otherwise, the point is outside the element, and if no element filters were used in the query, outside the FEM model itself.

Typically, it is preferred attach a point to an element only if it lies on or inside an element. However, it is possible to attach points outside an element as long as the system is able to determine appropriate element “coordinates” for that point (which it may not be able to do if the point is far away). In addition, the motion behavior of an exterior attached point may sometimes appear counterintuitive.

The FemModel3d element and node queries can be used in a variety of ways.

findNearestNodes() can be used to find all nodes within a certain distance of a point, as part of the process of making nodal-based attachments (Section 1.4.8).

findNearestNode() is used in the FemMuscleBeam example (Section 1.9.5) to determine if a desired muscle point is near enough to a node to use that node directly, or if a marker should be created.

As another example, suppose we wish to connect the surface nodes of an FEM model femA to the surface elements of another model femB if they lie within a prescribed distance tol of the surface of femB. Then we could use the following code:

Finally, it is possible to identify nodes on the surface of an FEM model according to whether they belong to specific features, such as a smooth patch or a sharp edge line. Methods for doing this are provided as static methods in the class FemQuery, and include:

| Feature based node queries: | |

|---|---|

| ArrayList<FemNode3d> findPatchNodes ( MFemModel3d fem, FemNode3d node0, double maxBendAng) |

Find nodes in patch defined by a maximum bend angle. |

| ArrayList<FemNode3d> findPatchBoundaryNodes ( MFemModel3d fem, FemNode3d node0, double maxBendAng) |

Find the border nodes of a patch. |

| ArrayList<FemNode3d> findEdgeLineNodes ( MFemModel3d fem, FemNode3d node0, double minBendAng, Mdouble maxEdgeAng, double allowBranching) |

Find the nodes along an edge defined by a minimum bend angle. |

Details of how these methods work are given in their API documentation. They use the notion of a bend angle, which is the absolute value of the angle between two faces about their common edge. A patch is defined by a collection of faces whose bend angles do not exceed a minimum value, while an edge line is a collection of edges with bend angles not below a maximum value. The feature methods start with an initial node (node0) and then grow the requested feature out from there. For example, suppose we have a regular hexahedral FEM grid, and we wish to find all the nodes on one of the faces. If we know one of the nodes on the face, then we can find all of the nodes using findPatchNodes:

Note that the feature query above uses a maximum bend angle of

![]() . Because grid faces are flat, this choice is somewhat

arbitrary; any angle larger than 0 (within machine precision) would also

work.

. Because grid faces are flat, this choice is somewhat

arbitrary; any angle larger than 0 (within machine precision) would also

work.

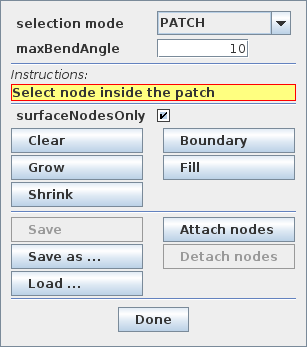

1.4.6 Selecting nodes in the viewer

Often, it is most convenient to select nodes in the ArtiSynth viewer. For this, a node selection tool is available (Figure 1.8), as described in the section “Selecting FEM nodes” of the ArtiSynth User Interface Guide). It allows nodes to be selected in various ways, including the usual click, drag box and elliptical selection tools, as well as specialized operations that select nodes based on patches, edge lines, and distances to other bodies. Once nodes have been selected, their numbers can be saved to a node number file which can then be read by a model’s build() method to determine which nodes to connect to some body.

Node number files are text files with a very simple format, consisting of integers (the node numbers), separated by white space. There is no limit to how many numbers can appear on a line but typically this is limited to ten or so to make the file more readable. Optionally, the numbers can be surrounded by square brackets ([ ]). The special character ‘#’ is a comment character, commenting out all characters from itself to the end of the current line. For a file containing the node numbers 2, 12, 4, 8, 23 and 47, the following formats are all valid:

Once node numbers have been identified in the viewer and saved in a file, they can be read by the build() method using a NodeNumberReader. For convenience, this class supplies two static methods for extracting the FEM nodes specified by the numbers in a file:

| static ArrayList<FemNode3d> read( MFile file, FemModel3d fem) |

Returns nodes in fem corresponding to file’s numbers. |

| static ArrayList<FemNode3d> read( MString filePath, FemModel3d fem) |

Returns nodes in fem corresponding to file’s numbers. |

Extracted nodes can be used to set boundary conditions or form connections with other bodies. For example, suppose we wish to connect a face of an FEM model fem to a rigid body block, using a set of nodes specified in a file called faceNodes.txt. A code fragment to accomplish this could be the following:

The process of selecting nodes in the viewer, saving them in a file, and using them in a model can be done iteratively: if the selected nodes need to be adjusted, one can reopen the node selection tool, load the selection from file, adjust the selection, and resave the file, without needing to make any modifications to the model’s build() code.

If desired, one can also determine a set of nodes in code, and then write their numbers to a file using the class NodeNumberWriter, which supplies static methods for writing number files:

| static void write( MString filePath, Collection<FemNode3d> nodes) |

Writes the numbers of nodes to the specified file. |

| static void write( MFile file, Collection<FemNode3d> nodes) |

Writes the numbers of nodes to file. |

| static void write( MFile file, Collection<FemNode3d> nodes, Mint maxCols, int flags) |

Writes the numbers of nodes to file, using the specified number of columns and format flags. |

For example:

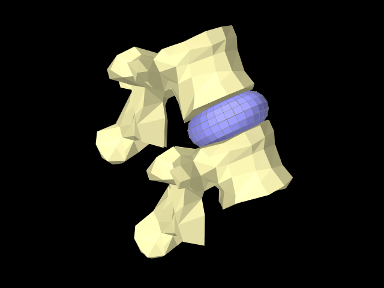

1.4.7 Example: two bodies connected by an FEM “spring”

The LumbarFrameSpring example in Section LABEL:LumbarFrameSpring:sec uses a frame spring to connect two simplified lumbar vertebrae. However, it is also possible to use an FEM model in place of a frame spring, possibly providing a more realistic model of the intervertebral disc. A simple model which does this is defined in

artisynth.demos.tutorial.LumbarFEMDisk

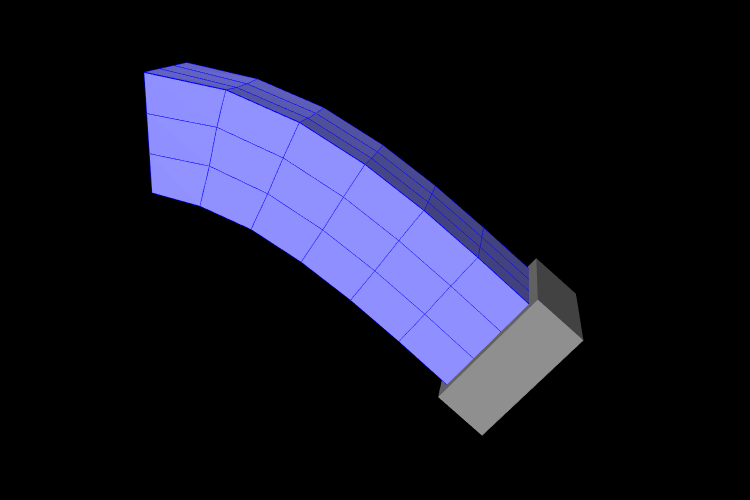

The initial source code is similar to that for LumbarFrameSpring, but differs in the section where the FEM disk replaces the FrameSpring:

The simplified FEM model representing the “disk” is created at lines 57-61, using a torus-shaped model created by FemFactory. It is then repositioning using transformGeometry() ( Section LABEL:TransformingGeometry:sec) to place it between the vertebrae (line 64-66). After the FEM model is positioned, we find which nodes are within a distance tol of each vertebral surface and attach them to the appropriate body (lines 69-81).

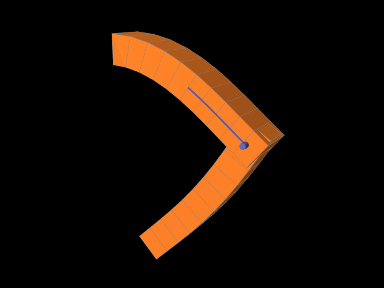

To run this example in ArtiSynth, select All demos > tutorial > LumbarFEMDisk from the Models menu. The model should load and initially appear as in Figure 1.9. The behavior is best seem by running the model and using the pull controller to exert forces on the upper vertebra.

1.4.8 Nodal-based attachments

The example of Section 1.4.4 uses element-based attachments to connect the nodes of one FEM to elements of another. As mentioned above, element-based attachments assume that the attached point is associated with a specific FEM model element. While this often gives good results, there are situations where it may be desirable to distribute the connection more broadly among a larger set of nodes.

In particular, this is sometimes the case when connecting FEM models to point-to-point springs. The end-point of such a spring may end up exerting a large force on the FEM, and then if the number of nodes to which the end-point is attached are too small, the resulting forces on these nodes (Equation 1.4) may end up being too large. In other words, it may be desirable to distribute the spring’s force more evenly throughout the FEM model.

To handle such situations, it is possible to create a nodal-based attachment in which the nodes and weights are explicitly specified. This involves explicitly creating a PointFem3dAttachment for the point or particle to be attached and the specifying the nodes and weights directly,

where nodes and weights are arrays of FemNode and double, respectively. It is up to the application to determine these.

PointFem3dAttachment provides several methods for explicitly specifying nodes and weights. The signatures for these include:

The last two methods determine the weights automatically, using an

inverse-distance-based calculation in which each weight ![]() is initially computed as

is initially computed as

| (1.4) |

where ![]() is the distance from node

is the distance from node ![]() to pos and

to pos and

![]() is the maximum distance. The weights are then

adjusted to ensure that they sum to one and that the weighted sum of

the nodes equals pos. In some cases, the specified nodes

may not provide enough support for the last condition to be

met, in which case the methods return false.

is the maximum distance. The weights are then

adjusted to ensure that they sum to one and that the weighted sum of

the nodes equals pos. In some cases, the specified nodes

may not provide enough support for the last condition to be

met, in which case the methods return false.

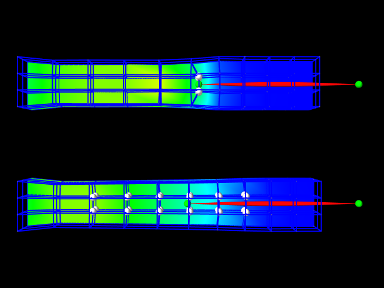

1.4.9 Example: element vs. nodal-based attachments

The model demonstrating the difference between element and nodal-based attachments is defined in

artisynth.demos.tutorial.PointFemAttachment

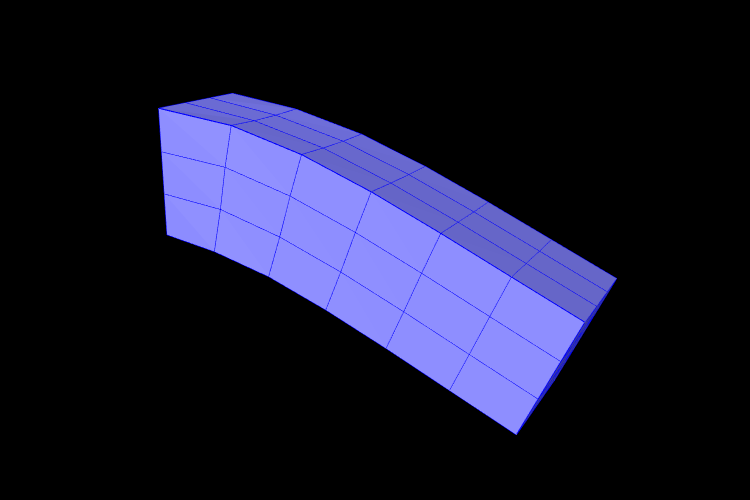

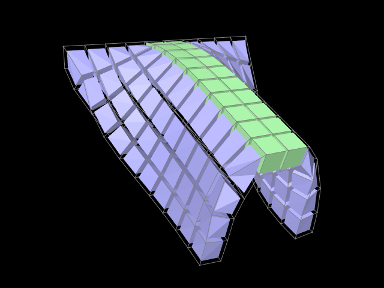

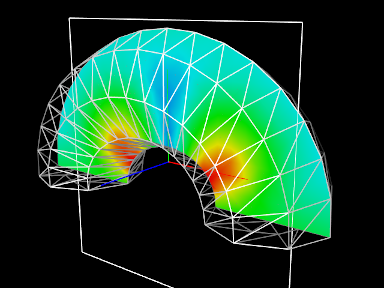

It creates two FEM models, each with a single point-to-point spring attached to a particle at their center. The model at the top (fem1 in the code below) is connected to the particle using an element-based attachment, while the lower model (fem2 in the code) is connected using a nodal-based attachment with a larger number of nodes. Figure 1.10 shows the result after the model is run until stable. The element-based attachment results in significantly higher deformation in the immediate vicinity around the attachment, while for the nodal-based attachment, the deformation is distributed much more evenly through the model.

The build method and some of the auxiliary code for this model is shown below. Code for the other auxiliary methods, including addFem(), addParticle(), addSpring(), and setAttachedNodesWhite(), can be found in the actual source file.

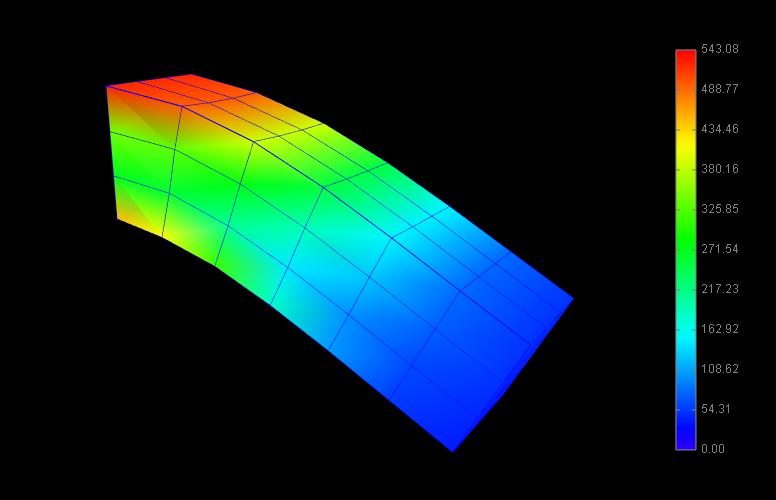

The build() method begins by creating a MechModel and then adding to it two FEM beams (created using the auxiliary method addFem(). Rendering of each FEM model’s surface is then set up to show strain values (setSurfaceRendering(), lines 41 and 43). The surface meshes themselves are also redefined to exclude the frontmost elements, allowing the strain values to be displayed closer model centers. This redefinition is done using calls to createSurfaceMesh() (lines 40, 41) with a custom ElementFilter defined at lines 3-12.

Next, the end-point particles for the axial springs are created (using the auxiliary method addParticle(), lines 46-49), and particle m1 is attached to fem1 using mech.attachPoint() (line 52), which creates an element-based attachment at the point’s current location. Point m2 is then attached to fem2 using a nodal-based attachment. The nodes for these are collected as the union of all nodes for a specified set of elements (lines 58-59, and the method collectNodes() defined at lines 16-25). These are then used to create a nodal-based attachment (lines 61-63), where the weights are determined automatically using the method associated with equation (1.4).

Finally, the springs are created (auxiliary method addSpring(), lines 66-67), the nodes associated for each attachment are set to render as white spheres (setAttachedNodesWhites(), lines 70-71), and the particles are set to render as green spheres.

To run this example in ArtiSynth, select All demos > tutorial > PointFemAttachment from the Models menu. Running the model will cause it to settle into the state shown in Figure 1.10. Selecting and dragging one of the spring anchor points at the right will cause the spring tension to vary and further illustrate the difference between the element and nodal-based attachments.

1.5 FEM markers

Just as there are FrameMarkers to act as anchor points on a frame or rigid body (Section LABEL:FrameMarkers:sec), there are also FemMarkers that can mark a point inside a finite element. They are frequently used to provide anchor points for attaching springs and forces to a point inside an element, but can also be used for graphical purposes.

FEM markers are implemented by the class FemMarker, which is a subclass of Point. They are essentially massless points that contain their own attachment component, so when creating and adding a marker there is no need to create a separate attachment component.

Within the component hierarchy, FEM markers are typically stored in the markers list of their associated FEM model. They can be created and added using a code fragment of the form

This creates a marker at the location ![]() (in world

coordinates), calls setFromFem() to attach it to the nearest

element in the FEM model ( which is either the containing element or

the nearest element on the model’s surface), and then adds it to the

markers list.

(in world

coordinates), calls setFromFem() to attach it to the nearest

element in the FEM model ( which is either the containing element or

the nearest element on the model’s surface), and then adds it to the

markers list.

If the marker’s attachment has not already been set when addMarker() is called, then addMarker() will call setFromFem() automatically. Therefore the above code fragment is equivalent to the following:

Alternatively, one may want to explicitly specify the nodes associated with the attachment, as described in Section 1.4.8:

There are a variety of methods available to set the attachment, mirroring those available in the underlying base class PointFem3dAttachment:

The last two methods compute nodal weights automatically, as described in Section 1.4.8, based on the marker’s currently assigned position. If the supplied nodes do not provide sufficient support, then the methods return false.

Another set of convenience methods are supplied by FemModel3d, which combine these with the addMarker() call:

For example, one can do

Markers are often used to track movement within an FEM model. For that, one can examine their positions and velocities, as with any other particles, using the methods

The return values from these methods should not be

modified. Alternatively, when a 3D force ![]() is applied to the

marker, it is distributed to the attached nodes according to the nodal

weights, as described in Equation (1.4).

is applied to the

marker, it is distributed to the attached nodes according to the nodal

weights, as described in Equation (1.4).

1.5.1 Example: attaching an FEM beam to a muscle

A complete application model that employs a fem marker as an anchor for a spring is given below.

This example can be found in artisynth.demos.tutorial.FemBeamWithMuscle. This model extends the FemBeam example, adding a FemMarker for the spring to attach to. The method createMarker(...) on lines 29–35 is used to create and add a marker to the FEM. Since the element is initially set to null, when it is added to the FEM, the model searches for the containing or nearest element. The loaded model is shown in Figure 1.11.

1.6 Frame attachments

It is also possible to attach frame components, including rigid bodies, directly to FEM models, using the attachment component FrameFem3dAttachment. Analogously to PointFem3dAttachment, the attachment is implemented by connecting the frame to a set of FEM nodes, and attachments can be either element-based or nodal-based. The frame’s origin is computed in the same way as for point attachments, using a weighted sum of node positions (Equation 1.3), while the orientation is computed using a polar decomposition on a deformation gradient determined from either element shape functions (for element-based attachments) or a Procrustes type analysis using nodal rest positions (for nodal-based attachments).

An element-based attachment can be created using either a code fragment of the form

or, equivalently, the attachFrame() method in MechModel:

This attaches the frame frame to the nodes of the FEM element elem. As with PointFem3dAttachment, if the frame’s origin is not inside the element, it may not be possible to accurately compute the internal nodal weights, in which case setFromElement() will return false.

In order to have the appropriate element located automatically, one can instead use

or, equivalently,

As with point-to-FEM attachments, it may be desirable to create a nodal-based attachment in which the nodes and weights are not tied to a specific element. The reasons for this are generally the same as with nodal-based point attachments (Section 1.4.8): the need to distribute the forces and moments acting on the frame across a broader set of element nodes. Also, element-based frame attachments use element shape functions to determine the frame’s orientation, which may produce slightly asymmetric results if the frame’s origin is located particularly close to a specific node.

FrameFem3dAttachment provides several methods for explicitly specifying nodes and weights. The signatures for these include:

Unlike their counterparts in PointFem3dAttachment, the first two methods also require the current desired pose of the frame TFW (in world coordinates). This is because while nodes and weights will unambiguously specify the frame’s origin, they do not specify the desired orientation.

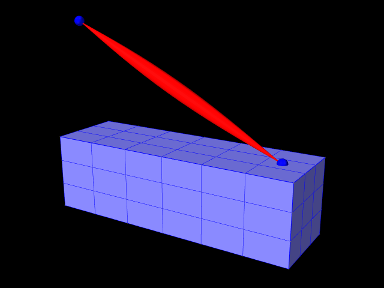

1.6.1 Example: attaching frames to an FEM beam

A model illustrating how to connect frames to an FEM model is defined in

artisynth.demos.tutorial.FrameFemAttachment

It creates an FEM beam, along with a rigid body block and a massless coordinate frame, that are then attached to the beam using nodal and element-based attachments. The build method is shown below:

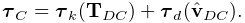

Lines 3-22 create a MechModel and populate it with an FEM beam and a rigid body box. Next, a basic Frame is created, with a specified pose and an axis length of 0.3 (to allow it to be seen), and added to the MechModel (lines 25-28). It is then attached to the FEM beam using an element-based attachment (line 30). Meanwhile, the box is attached to using a nodal-based attachment, created from all the nodes associated with elements 22 and 31 (lines 33-36). Finally, all attachment nodes are set to be rendered as green spheres (lines 39-41).

To run this example in ArtiSynth, select All demos > tutorial > FrameFemAttachment from the Models menu. Running the model will cause it to settle into the state shown in Figure 1.12. Forces can interactively be applied to the attached block and frame using the pull tool, causing the FEM model to deform (see the section “Pull Manipulation” in the ArtiSynth User Interface Guide).

1.6.2 Adding joints to FEM models

The ability to connect frames to FEM models, as described in Section 1.6, makes it possible to interconnect different FEM models directly using joints, as described in Section LABEL:JointsAndConnectors:sec. This is done internally by using FrameFem3dAttachments to connect frames C and D of the joint (Figure LABEL:jointExample:fig) to their respective FEM models.

As indicated in Section LABEL:CreatingJoints:sec, most joints have a constructor of the form

that creates a joint connecting bodyA to bodyB, with the initial pose of the D frame given (in world coordinates) by TDW. The same body and transform settings can be made on an existing joint using the method setBodies(bodyA, bodyB, TDW). For these constructors and methods, it is possible to specify FEM models for bodyA and/or bodyB. Internally, the joint then creates a FrameFem3dAttachment to connect frame C and/or D of the joint (See Figure LABEL:jointExample:fig) to the corresponding FEM model.

However, unlike joints involving rigid bodies or frames, there are no

associated ![]() or

or ![]() transforms (since there is no fixed

frame within an FEM to define such transforms). Methods or

constructors which utilize

transforms (since there is no fixed

frame within an FEM to define such transforms). Methods or

constructors which utilize ![]() or

or ![]() can therefore

not be used with FEM models.

can therefore

not be used with FEM models.

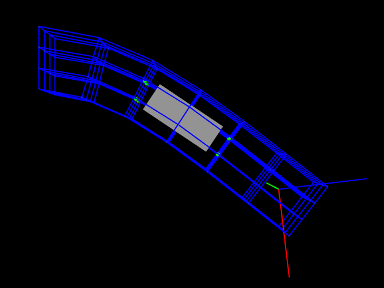

1.6.3 Example: two FEM beams connected by a joint

A model connecting two FEM beams by a joint is defined in

artisynth.demos.tutorial.JointedFemBeams

It creates two FEM beams and connects them via a special slotted-revolute joint. The build method is shown below:

Lines 3-16 create a MechModel and populates it with two FEM beams, fem1 and fem2, using an auxiliary method addFem() defined in the model source file. The leftmost nodes of fem1 are set fixed. A SlottedRevoluteJoint is then created to interconnect fem1 and fem2 at a location specified by TDW (lines 19-21). Lines 24-29 set some parameters for the joint, along with various render properties.

To run this example in ArtiSynth, select All demos > tutorial > JointedFemBeams from the Models menu. Running the model will cause it drop and flex under gravity, as shown in 1.13. Forces can interactively be applied to the beams using the pull tool (see the section “Pull Manipulation” in the ArtiSynth User Interface Guide).

1.7 Incompressibility

FEM incompressibility within ArtiSynth is enforced by trying to ensure that the volume of an FEM remains locally constant. This, in turn, is accomplished by constraining nodal velocities so that the local volume change, or divergence, is zero (or close to zero). There are generally two ways to do this:

-

•

Hard incompressibility, which sets up explicit constraints on the nodal velocities;

-

•

Soft incompressibility, which uses a restoring pressure based on a potential field to try to keep the volume constant.

Both of these methods operate independently, and both can be used either separately or together. Generally speaking, hard incompressibility will result in incompressibility being more rigorously enforced, but at the cost of increased computation time and (sometimes) less stability. Soft incompressibility allows the application to control the restoring force used to enforce incompressibility, usually by adjusting the value of the bulk modulus material property. As the bulk modulus is increased, soft incompressibility starts to act more like ‘hard’ incompressibility, with an infinite bulk modulus corresponding to perfect incompressibility. However, very large bulk modulus values will generally produce stability problems.

Incompressibility is not currently implemented for shell elements. Applying hard incompressibility to a shell element will have no effect on its behavior. If soft incompressibility is applied, by supplying the element with an incompressible material, then only the deviatoric component of that material will have any effect; the dilational component will generate no stress.

1.7.1 Volume regions and locking

Both hard and soft incompressibility can be applied to different regions of local volume. From larger to smaller, these regions are:

-

•

Nodal - the local volume surrounding each node;

-

•

Element - the volume of each element;

-

•

Full - the volume at each integration point.

Element-based incompressibility is the standard method generally seen

in the literature. However, it tends not to work well for

tetrahedral meshes, because constraining the volume of each tet in a

tetrahedral mesh tends to over constrain the system. This is because

the number of tets in a large tetrahedral mesh is often ![]() ,

where

,

where ![]() is the number of nodes, and so putting a volume constraint

on each element may result in

is the number of nodes, and so putting a volume constraint

on each element may result in ![]() constraints, which exceeds the

constraints, which exceeds the

![]() degrees of freedom (DOF) in the FEM. This overconstraining results in an

artificially increased stiffness known as locking. Because of

locking, for tetrahedrally based meshes it may be better to use

nodal-based incompressibility, which creates a single volume constraint

around each node, resulting in only

degrees of freedom (DOF) in the FEM. This overconstraining results in an

artificially increased stiffness known as locking. Because of

locking, for tetrahedrally based meshes it may be better to use

nodal-based incompressibility, which creates a single volume constraint

around each node, resulting in only ![]() constraints, leaving

constraints, leaving ![]() DOF

to handle the remaining deformation. However, nodal-based

incompressibility is computationally more costly than element-based

and may not be as stable.

DOF

to handle the remaining deformation. However, nodal-based

incompressibility is computationally more costly than element-based

and may not be as stable.

Generally, the best solution for incompressible problems is to use

element-based incompressibility with a mesh consisting of hexahedra,

or primarily hexahedra and a mix of other elements (the latter

commonly being known as a hex dominant mesh). For hex-based

meshes, the number of elements is roughly equal to the number of

nodes, and so adding a volume constraint for each element imposes ![]() constraints on the model, which (like nodal incompressibility)

leaves

constraints on the model, which (like nodal incompressibility)

leaves ![]() DOF to handle the remaining deformation.

DOF to handle the remaining deformation.

Full incompressibility tries to control the volume at each integration point within each element, which almost always results in a large number of volumetric constraints and hence locking. It is therefore not commonly used and is provided mostly for debugging and diagnostic purposes.

1.7.2 Hard incompressibility

Hard incompressibility is controlled by the incompressible property of the FEM, which can be set to one of the following values of the enumerated type FemModel.IncompMethod:

- OFF

-

No hard incompressibility enforced.

- ELEMENT

-

Element-based hard incompressibility enforced (Section 1.7.1).

- NODAL

-

Nodal-based hard incompressibility enforced (Section 1.7.1).

- AUTO

-

Selects either ELEMENT or NODAL, with the former selected if the number of elements is less than or equal to the number of nodes.

- ON

-

Same as AUTO.

Hard incompressibility uses explicit constraints on the nodal velocities to enforce the incompressibility, which increases computational cost. Also, if the number of constraints is too large, perturbed pivot errors may be encountered by the solver. However, hard incompressibility can in principle handle situations where complete incompressibility is required. It is equivalent to the mixed u-P formulation used in commercial FEM codes (such as ANSYS), and the Lagrange multipliers computed for the constraints are pressure impulses.

Hard incompressibility can be applied in addition to soft incompressibility, in which case it will provide additional incompressibility enforcement on top of that provided by the latter. It can also be applied to linear materials, which are not themselves able to emulate true incompressible behavior (Section 1.7.4).

1.7.3 Soft incompressibility

Soft incompressibility enforces incompressibility using a restoring

pressure that is controlled by a volume-based energy potential. It is

only available for FEM materials that are subclasses of

IncompressibleMaterial.

The energy potential ![]() is a function of the determinant

is a function of the determinant ![]() of the

deformation gradient, and is scaled by the material’s bulk modulus

of the

deformation gradient, and is scaled by the material’s bulk modulus

![]() . The restoring pressure

. The restoring pressure ![]() is given by

is given by

| (1.5) |

Different potentials can be selected by setting the bulkPotential property of the incompressible material, whose value is an instance of IncompressibleMaterial.BulkPotential. Currently there are two different potentials:

- QUADRATIC

-

The potential and associated pressure are given by

(1.6) - LOGARITHMIC

-

The potential and associated pressure are given by

(1.7)

The default potential is QUADRATIC, which may provide slightly improved stability characteristics. However, we have not noticed significant differences between the two potentials in practice.

How soft incompressibility is applied within an FEM model is controlled by the FEM’s softIncompMethod property, which can be set to one of the following values of the enumerated type FemModel.IncompMethod:

- ELEMENT

-

Element-based soft incompressibility enforced (Section 1.7.1).

- NODAL

-

Nodal-based soft incompressibility enforced (Section 1.7.1).

- AUTO

-

Selects either ELEMENT or NODAL, with the former selected if the number of elements is less than or equal to the number of nodes.

- FULL

-

Incompressibility enforced at each integration point (Section 1.7.1).

1.7.4 Incompressibility and linear materials

Within a linear material, incompressibility is controlled by Poisson’s

ratio ![]() , which for isotropic materials can assume a value in the

range

, which for isotropic materials can assume a value in the

range ![]() . This specifies the amount of transverse contraction

(or expansion) exhibited by the material as it compressed or extended

along a particular direction. A value of

. This specifies the amount of transverse contraction

(or expansion) exhibited by the material as it compressed or extended

along a particular direction. A value of ![]() allows the material to be

compressed or extended without any transverse contraction or

expansion, while a value of

allows the material to be

compressed or extended without any transverse contraction or

expansion, while a value of ![]() in theory indicates a perfectly

incompressible material. However, setting

in theory indicates a perfectly

incompressible material. However, setting ![]() in practice

causes a division by zero, so only values close to 0.5 (such as 0.49)

can be used.

in practice

causes a division by zero, so only values close to 0.5 (such as 0.49)

can be used.

Moreover, the incompressibility only applies to small displacements,

so that even with ![]() it is still possible to squash a linear

FEM completely flat if enough force is applied. If true incompressible

behavior is desired with a linear material, then one must also use

hard incompressibility (Section 1.7.2).

it is still possible to squash a linear

FEM completely flat if enough force is applied. If true incompressible

behavior is desired with a linear material, then one must also use

hard incompressibility (Section 1.7.2).

1.7.5 Using incompressibility in practice

As mentioned above, when modeling incompressible models, we have found that the best practice is to use, if possible, either a hex or hex-dominant mesh, along with element-based incompressibility.

Hard incompressibility allows the handling of full incompressibility but at the expense of greater computational cost and often less stability. When modeling biomechanical materials, it is often permissible to use only soft incompressibility, partly since biomechanical materials are rarely completely incompressible. When implementing soft incompressibility, it is common practice to set the bulk modulus to something like 100 times the other (deviatoric) stiffnesses of the material.

We have found stability behavior to be complex, and while hard incompressibility often results in less stable behavior, this is not always the case: in some situations the stronger enforcement afforded by hard incompressibility actually improves stability.

1.8 Varying and augmenting material behaviors

The default material used by all elements of an FEM model is supplied by the model’s material property. However, it is often the case that one wishes to specify different material behaviors for different sets of elements within an FEM model. This may be particularly true when combining volumetric and shell elements.

There are several ways to vary material behavior within a model. These include:

-

•

Setting an explicit material for specific elements, using their material property. An element’s material is null by default, but if set to a material, it will override the default material supplied by the FEM model. While this method is quite straightforward, it does have one disadvantage: because material settings are copied by each element, subsequent interactive or online changes to the material require resetting the material in all the affected elements.

-

•

Binding one or more material parameters to a field. Sometimes certain material parameters, such as stiffness quantities or direction information, may need to vary across the FEM domain. While sometimes this can be handled by setting material properties for specific elements, it may be more convenient to bind the varying properties to a field, which can specify varying values over a domain composed of either a regular grid or an FEM mesh. Only one material needs to be used, and any properties which are not bound can be adjusted interactively or online. Fields and their bindings are described in detail in Chapter LABEL:sec:fields.

-

•

Adding augmenting material behaviors using MaterialBundles. A material bundle may be specified either for all elements, or for a subset of them, and each provides one material (via its own material property) whose behavior is added to that of the indicated elements. This also provides an easy way to combine the behaviors of two of more materials in the same element. One also has the option of setting the material property of the certain elements to NullMaterial, so that only the augmenting material(s) are applied.

-

•

Adding muscle behaviors using MuscleBundles. This is analogous to using MaterialBundles, except that MuscleBundles are restricted to using an instance of a MuscleMaterial, and include support for handling the excitation value, as well as the activation directions (which usually vary across the FEM domain). MuscleBundles are only present in the FemMuscleModels subclass of FemModel3d, and are described in detail in Section 1.9.

The remainder of this section will discuss MaterialBundles.

Adding a MaterialBundle to an FEM model is illustrated by the following code fragment:

Once added, the stress computed by the bundle’s material will be added to the stress computed by any other materials which are active for the bundle’s elements.

When deciding what elements to add to a bundle, one is free to choose any means necessary. The example above inspects all the volumetric elements in the FEM. To instead inspect all the shell elements, or all volumetric and shell elements, one could use the code fragments such as the following:

Of course, if the elements are known through other means, then they can be added directly.

The element composition of a bundle can be controlled by the methods

It is also possible to create a MaterialBundle whose material is added to all the FEM elements. This can done either by using one of the following constructors

with useAllElements set to true, or by calling the method

When a bundle is set to use all the FEM elements, it clears its own element list, and one is not permitted to add elements using addElement(elem).

After a bundle has been created, it is possible to get or set its material property using the methods

Again, because materials are copied internally, any modification to a material after it has been used as an input to setMaterial() will not be noticed by the bundle. Instead, one should modify the material before calling setMaterial(), or modify the copied material which can be obtained by calling getMaterial() or by storing the value returned by setMaterial().

Finally, a MuscleBundle is a renderable component. Setting its elementWidgetSize property to a value greater than zero will cause the rendering of all its elements, using a solid widget representation of each at a scale controlled by elementWidgetSize: 0.5 for half size, 1.0 for full size, etc. The color of the widgets is controlled by the faceColor property of the bundle’s renderProps. Being able to render the elements makes it easy to select the bundle and visualize which elements it contains.

1.8.1 Example: FEM sheet with a stiff spine

A simple model demonstrating the use of material bundles is defined in

artisynth.demos.tutorial.MaterialBundleDemo