6.10 Material types

ArtiSynth FEM models support a variety of material types, including

linear, hyperelastic, and activated muscle materials, described in the

sections below. These can be used to supply the primary material for

either an entire FEM model or for specific elements (using the setMaterial() methods for either). They can also be used to supply

auxiliary materials, whose behavior is superimposed on the underlying

material, via either material bundles

(Section 6.8) or,

for FemMuscleModels, muscle bundles

(Section 6.9). Many of the properties for a given

material can be bound to a scalar or vector field

(Section 7.2) to allow their values to vary across an

FEM model. In the descriptions below, properties for which this is

true will have a ![]() indicated under the “Field” entry in the

material’s property table.

indicated under the “Field” entry in the

material’s property table.

All materials are defined in the package artisynth.core.materials.

6.10.1 Linear

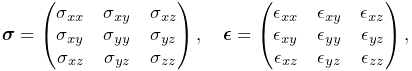

Linear materials determine Cauchy stress ![]() as a linear mapping

from the small deformation Cauchy strain

as a linear mapping

from the small deformation Cauchy strain ![]() ,

,

| (6.8) |

where ![]() is the elasticity tensor.

Both the stress and

strain are symmetric

is the elasticity tensor.

Both the stress and

strain are symmetric ![]() matrices,

matrices,

|

(6.9) |

and can be expressed as 6-vectors using Voigt notation:

|

(6.10) |

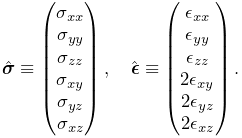

This allows the constitutive mapping to be expressed in matrix form as

| (6.11) |

where ![]() is the

is the ![]() elasticity matrix.

elasticity matrix.

Different Voigt notation mappings appear in the literature with regard to off-diagonal matrix entries. We use the one employed by FEBio [13]. Another common mapping is

Traditionally, Cauchy strain is computed from the symmetric part of

the deformation gradient ![]() using the formula

using the formula

| (6.12) |

where ![]() is the

is the ![]() identity matrix. However, ArtiSynth

materials support corotation, in which rotations are first

removed from

identity matrix. However, ArtiSynth

materials support corotation, in which rotations are first

removed from ![]() using a polar decomposition

using a polar decomposition

| (6.13) |

where ![]() is a (right-handed) rotation matrix and

is a (right-handed) rotation matrix and ![]() is symmetric

matrix.

is symmetric

matrix. ![]() is then used to compute the Cauchy strain:

is then used to compute the Cauchy strain:

| (6.14) |

Corotation is the default behavior for linear materials in ArtiSynth and allows models to handle large scale rotational deformations [18, 16].

For linear materials, the stress/strain response is computed at a single integration point in the center of each element. This is done

to improve computational efficiency, as it allows the precomputation

of stiffness matrices that map nodal displacements onto nodal forces

for each element. This precomputed matrix can then be adjusted during

each simulation step to account for the rotation ![]() computed at each

element’s integration

point [18, 16].

computed at each

element’s integration

point [18, 16].

Specific linear material types are listed in the subsections below. All are subclasses of LinearMaterialBase, and in addition to their individual properties, all export a corotation property (default value true) that controls whether corotation is applied.

6.10.1.1 LinearMaterial

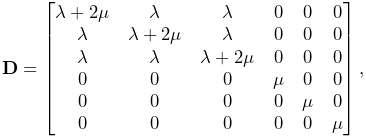

LinearMaterial is a standard isotropic linear material, which is also the default material for FEM models. Its elasticity matrix is given by

|

(6.15) |

where the Lamé parameters ![]() and

and ![]() are

derived from Young’s modulus

are

derived from Young’s modulus ![]() and Poisson’s ratio

and Poisson’s ratio ![]() via

via

| (6.16) |

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| YoungsModulus | Young’s modulus | 500000 | ✓ | |

| PoissonsRatio | Poisson’s ratio | 0.33 | ||

| corotated | applies corotation if true | true |

LinearMaterials can be created with the following constructors:

| LinearMaterial() |

Create with default properties. |

| LinearMaterial (double E, double nu) |

Create with specified |

| LinearMaterial (double E, double nu, boolean corotated) |

Create with specified |

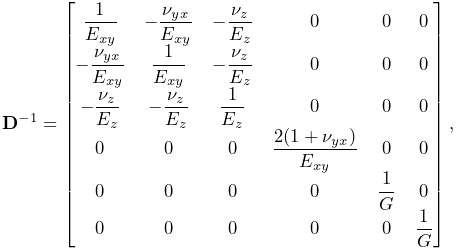

6.10.1.2 TransverseLinearMaterial

TransverseLinearMaterial

is a transversely isotropic linear material whose behavior is

symmetric about a prescribed polar axis. If the polar axis is

parallel to the ![]() axis, then the elasticity matrix is specified most

easily in terms of its inverse, or compliance matrix, according

to

axis, then the elasticity matrix is specified most

easily in terms of its inverse, or compliance matrix, according

to

|

where ![]() and

and ![]() are Young’s moduli transverse

and parallel to the axis, respectively,

are Young’s moduli transverse

and parallel to the axis, respectively, ![]() and

and ![]() are

Poisson’s ratios transverse and parallel to the axis, and

are

Poisson’s ratios transverse and parallel to the axis, and ![]() is the

shear modulus.

is the

shear modulus.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| youngsModulus | Young’s moduli transverse and parallel to the axis | ✓ | ||

| poissonsRatio | Poisson’s ratios transverse and parallel to the axis | |||

| shearModulus | shear modulus | 187970 | ✓ | |

| direction | direction of the polar axis | ✓ | ||

| corotated | applies corotation if true | true |

The youngsModulus and poissonsRatio properties are both described by Vector2d objects, while direction is described by a Vector3d. The direction property (as well as youngsModulus and shearModulus) can be bound to a field to allow its value to vary over an FEM model (Section 7.2).

TransverseLinearMaterials can be created with the following constructors:

| TransverseLinearMaterial() |

Create with default properties. |

| TransverseLinearMaterial (Vector2d E, double G, MVector2d nu, boolean corotated) |

Create with specified |

6.10.1.3 AnisotropicLinearMaterial

AnisotropicLinearMaterial

is a general anisotropic linear material whose behavior is specified

by an arbitrary (symmetric) elasticity matrix ![]() .

The material behavior is controlled by the following properties:

.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| stiffnessTensor | symmetric |

|||

| corotated | applies corotation if true | true |

The default value for stiffnessTensor is an isotropic elasticity

matrix corresponding to ![]() and

and ![]() .

.

AnisotropicLinearMaterials can be created with the following constructors:

| AnisotropicLinearMaterial() |

Create with default properties. |

| AnisotropicLinearMaterial (Matrix6dBase D) |

Create with specified elasticity |

| AnisotropicLinearMaterial (Matrix6dBase D, boolean corotated) |

Create with specified |

6.10.2 Hyperelastic materials

A hyperelastic material is defined by a strain energy density

function ![]() that is in general a function of the deformation gradient

that is in general a function of the deformation gradient

![]() , and more specifically a quantity derived from

, and more specifically a quantity derived from ![]() that is

rotationally invariant, such as the right Cauchy Green

tensor

that is

rotationally invariant, such as the right Cauchy Green

tensor ![]() , the left Cauchy Green

tensor

, the left Cauchy Green

tensor ![]() , or Green strain

, or Green strain

| (6.16) |

![]() is often described with respect to the first or second invariants

of these quantities, denoted by

is often described with respect to the first or second invariants

of these quantities, denoted by ![]() and

and ![]() and defined with

respect to a given matrix

and defined with

respect to a given matrix ![]() by

by

| (6.17) |

Alternatively, ![]() is sometimes defined with respect to the three

principal stretches of the deformation,

is sometimes defined with respect to the three

principal stretches of the deformation, ![]() , which are the eigenvalues of the symmetric component

, which are the eigenvalues of the symmetric component ![]() of the

polar decomposition of

of the

polar decomposition of ![]() in (6.13).

in (6.13).

If ![]() is expressed with respect to

is expressed with respect to ![]() , then the second

Piola-Kirchhoff stress

, then the second

Piola-Kirchhoff stress ![]() is given by

is given by

| (6.18) |

from which the Cauchy stress can be obtained via

| (6.19) |

Many of the hyperelastic materials described below are incompressible, in the sense that ![]() is partitioned into a deviatoric component that is volume invariant and a dilational

component that depends solely on volume changes.

Volume change is

characterized by

is partitioned into a deviatoric component that is volume invariant and a dilational

component that depends solely on volume changes.

Volume change is

characterized by ![]() , with the change in volume given by

, with the change in volume given by ![]() and

and ![]() indicating no volume change. Deviatoric

changes are characterized by

indicating no volume change. Deviatoric

changes are characterized by ![]() , with

, with

| (6.20) |

and so the partitioned strain energy density function assumes the form

| (6.21) |

where the ![]() term is the deviatoric contribution and

term is the deviatoric contribution and

![]() is the volumetric potential that enforces incompressibility.

is the volumetric potential that enforces incompressibility.

![]() may also be expressed with respect to the right deviatoric

Cauchy Green tensor

may also be expressed with respect to the right deviatoric

Cauchy Green tensor ![]() or the left deviatoric Cauchy Green

tensor

or the left deviatoric Cauchy Green

tensor ![]() , respectively defined by

, respectively defined by

| (6.22) |

ArtiSynth supplies different forms of ![]() , as specified by a

material’s bulkPotential property and detailed in

Section 6.7.3. All of the available potentials depend

on a bulkModulus property

, as specified by a

material’s bulkPotential property and detailed in

Section 6.7.3. All of the available potentials depend

on a bulkModulus property ![]() , and so

, and so ![]() is often

expressed as

is often

expressed as ![]() . A larger bulk modulus will make the

material more incompressible, with effective incompressibility

typically achieved by setting

. A larger bulk modulus will make the

material more incompressible, with effective incompressibility

typically achieved by setting ![]() to a value that exceeds the

other elastic moduli in the material by a factor of 100 or more.

All incompressible materials are subclasses of

IncompressibleMaterialBase.

to a value that exceeds the

other elastic moduli in the material by a factor of 100 or more.

All incompressible materials are subclasses of

IncompressibleMaterialBase.

6.10.2.1 St Venant-Kirchoff material

StVenantKirchoffMaterial

is a compressible isotropic material that extends isotropic linear

elasticity to large deformations.

The strain energy density is most easily expressed as a function

of the Green strain ![]() :

:

| (6.23) |

where the Lamé parameters ![]() and

and ![]() are

derived from Young’s modulus

are

derived from Young’s modulus ![]() and Poisson’s ratio

and Poisson’s ratio ![]() according to (6.16).

From this definition it follows that the second Piola-Kirchoff stress

tensor is given by

according to (6.16).

From this definition it follows that the second Piola-Kirchoff stress

tensor is given by

| (6.24) |

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| YoungsModulus | Young’s modulus | 500000 | ✓ | |

| PoissonsRatio | Poisson’s ratio | 0.33 |

StVenantKirchoffMaterials can be created with the following constructors:

| StVenantKirchoffMaterial() |

Create with default properties. |

| StVenantKirchoffMaterial (double E, double nu) |

Create with specified elasticity |

6.10.2.2 Neo-Hookean material

NeoHookeanMaterial

is a compressible isotropic material with a strain energy density

expressed as a function of the first invariant ![]() of the right

Cauchy-Green tensor

of the right

Cauchy-Green tensor ![]() and

and ![]() :

:

| (6.24) |

where the Lamé parameters ![]() and

and ![]() are derived from

Young’s modulus

are derived from

Young’s modulus ![]() and Poisson’s ratio

and Poisson’s ratio ![]() via

(6.16). The Cauchy stress can be expressed in terms of

the left Cauchy-Green tensor

via

(6.16). The Cauchy stress can be expressed in terms of

the left Cauchy-Green tensor ![]() as

as

| (6.25) |

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| YoungsModulus | Young’s modulus | 500000 | ✓ | |

| PoissonsRatio | Poisson’s ratio | 0.33 |

NeoHookeanMaterials can be created with the following constructors:

| NeoHookeanMaterial() |

Create with default properties. |

| NeoHookeanMaterial (double E, double nu) |

Create with specified elasticity |

6.10.2.3 Incompressible neo-Hookean material

IncompNeoHookeanMaterial

is an incompressible version of the neo-Hookean material,

with a strain energy density expressed in terms of the

first invariant ![]() of the deviatoric

right Cauchy-Green tensor

of the deviatoric

right Cauchy-Green tensor ![]() , plus a potential

function

, plus a potential

function ![]() to enforce incompressibility:

to enforce incompressibility:

| (6.25) |

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| shearModulus | shear modulus | 150000 | ✓ | |

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

IncompNeoHookeanMaterials can be created with the following constructors:

| IncompNeoHookeanMaterial() |

Create with default properties. |

| IncompNeoHookeanMaterial (double G, double kappa) |

Create with specified elasticity |

6.10.2.4 Mooney-Rivlin material

MooneyRivlinMaterial

is an incompressible isotropic material with a strain energy density

expressed as a polynomial of the first and second invariants ![]() and

and ![]() of the right deviatoric Cauchy-Green

tensor

of the right deviatoric Cauchy-Green

tensor ![]() . ArtiSynth supplies a five parameter version of this

model, with a strain energy density given by

. ArtiSynth supplies a five parameter version of this

model, with a strain energy density given by

| (6.25) |

A two-parameter version (![]() ,

, ![]() ) is often found in the

literature, consisting of only the first two terms:

) is often found in the

literature, consisting of only the first two terms:

| (6.26) |

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| C10 | first coefficient | 150000 | ✓ | |

| C01 | second coefficient | 0 | ✓ | |

| C11 | third coefficient | 0 | ✓ | |

| C20 | fourth coefficient | 0 | ✓ | |

| C02 | fifth coefficient | 0 | ✓ | |

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

MooneyRivlinMaterials can be created with the following constructors:

| MooneyRivlinMaterial() |

Create with default properties. |

| MooneyRivlinMaterial (double C10, double C01, double C11, Mdouble C20, double C02, double kappa) |

Create with specified coefficients. |

6.10.2.5 Ogden material

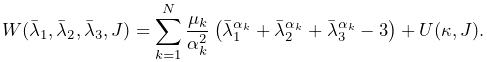

OgdenMaterial

is an incompressible material with a strain energy density

expressed as a function of the deviatoric principal stretches ![]() :

:

|

(6.26) |

ArtiSynth allows a maximum of six terms, corresponding to ![]() , and

the material behavior is controlled by the following properties:

, and

the material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| Mu1 | first multiplier | 300000 | ✓ | |

| Mu2 | second multiplier | 0 | ✓ | |

| ... | ... | ... | 0 | ✓ |

| Mu6 | final multiplier | 0 | ✓ | |

| Alpha1 | first multiplier | 2 | ✓ | |

| Alpha2 | second multiplier | 2 | ✓ | |

| ... | ... | ... | 2 | ✓ |

| Alpha6 | final multiplier | 2 | ✓ | |

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

OgdenMaterials can be created with the following constructors:

| OgdenMaterial() |

Create with default properties. |

| OgdenMaterial (double[] mu, double[] alpha, double kappa) |

Create with specified |

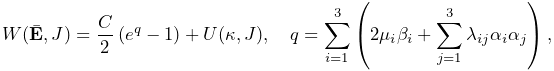

6.10.2.6 Fung orthotropic material

FungOrthotropicMaterial

is an incompressible orthotropic material defined with respect to an

![]() -

-![]() -

-![]() coordinate system expressed by a

coordinate system expressed by a ![]() rotation

matrix

rotation

matrix ![]() . The strain energy density is expressed as a function of

the deviatoric Green strain

. The strain energy density is expressed as a function of

the deviatoric Green strain

| (6.26) |

and the three unit direction vectors ![]() representing the columns of

representing the columns of ![]() . Letting

. Letting ![]() and defining

and defining

| (6.27) |

the energy density is given by

|

(6.28) |

where ![]() is a material coefficient and

is a material coefficient and ![]() and

and ![]() are

the orthotropic Lamé parameters.

are

the orthotropic Lamé parameters.

At present, the coordinate frame ![]() is not defined in the material,

but can be specified on a per-element basis using the element method

setFrame(Matrix3dBase). For example:

is not defined in the material,

but can be specified on a per-element basis using the element method

setFrame(Matrix3dBase). For example:

One should be careful to ensure that the argument to setFrame() is in fact an orthogonal rotation matrix as this will not be otherwise enforced.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| mu1 | second Lamé parameter along |

1000 | ✓ | |

| mu2 | second Lamé parameter along |

1000 | ✓ | |

| mu3 | second Lamé parameter along |

1000 | ✓ | |

| lam11 | first Lamé parameter along |

2000 | ✓ | |

| lam22 | first Lamé parameter along |

2000 | ✓ | |

| lam33 | first Lamé parameter along |

2000 | ✓ | |

| lam12 | first Lamé parameter for |

2000 | ✓ | |

| lam23 | first Lamé parameter for |

2000 | ✓ | |

| lam31 | first Lamé parameter for |

2000 | ✓ | |

| C | C coefficient | 1500 | ✓ | |

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

FungOrthotropicMaterials can be created with the following constructors:

| FungOrthotropicMaterial() |

Create with default properties. |

| FungOrthotropicMaterial (double mu1, double mu2, double mu3, Mdouble lam11, double lam22, double lam33, double lam12, Mdouble lam23, double lam31, double C, double kappa) |

Create with specified properties. |

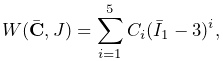

6.10.2.7 Yeoh material

YeohMaterial is an incompressible isotropic material that implements a Yeoh model with a strain energy density containing up to five terms:

|

(6.28) |

where ![]() is the first invariant of the right deviatoric Cauchy Green

tensor and

is the first invariant of the right deviatoric Cauchy Green

tensor and ![]() are the material coefficients.

The material behavior is controlled by the following properties:

are the material coefficients.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| C1 | first coefficient (shear modulus) | 150000 | ✓ | |

| C2 | second coefficient | 0 | ✓ | |

| C3 | third coefficient | 0 | ✓ | |

| C4 | fourth coefficient | 0 | ✓ | |

| C5 | fifth coefficient | 0 | ✓ | |

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

YeohMaterials can be created with the following constructors:

| YeohMaterial() |

Create with default properties. |

| YeohMaterial (double C1, double C2, double C3, double kappa) |

Create three term material with |

| YeohMaterial (double C1, double C2, double C3, double C4, Mdouble C5, double kappa) |

Create five term material with |

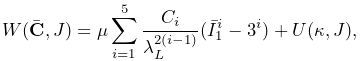

6.10.2.8 Arruda-Boyce material

ArrudaBoyceMaterial is an incompressible isotropic material that implements the Arruda-Boyce model [2]. Its strain energy density is given by

|

(6.28) |

where ![]() is the initial modulus,

is the initial modulus, ![]() the

locking stretch,

the

locking stretch, ![]() the first invariant of the

right deviatoric Cauchy Green tensor, and

the first invariant of the

right deviatoric Cauchy Green tensor, and

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| mu | initial modulus | 1000 | ✓ | |

| lambdaMax | locking stretch | 2.0 | ✓ | |

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

ArrudaBoyceMaterials can be created with the following constructors:

| ArrudaBoyceMaterial() |

Create with default properties. |

| ArrudaBoyceMaterial (double mu, double lmax, double kappa) |

Create with specified |

6.10.2.9 Veronda-Westmann material

VerondaWestmannMaterial is an incompressible isotropic material that implements the Veronda-Westmann model [28]. Its strain energy density is given by

| (6.29) |

where ![]() and

and ![]() are material coefficients and

are material coefficients and ![]() and

and

![]() the first and second invariants of the right deviatoric

Cauchy Green tensor.

the first and second invariants of the right deviatoric

Cauchy Green tensor.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| C1 | first coefficient | 1000 | ✓ | |

| C2 | second coefficient | 10 | ✓ | |

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

VerondaWestmannMaterials can be created with the following constructors:

| VerondaWestmannMaterial() |

Create with default properties. |

| VerondaWestmannMaterial (double C1, double C2, double kappa) |

Create with specified |

6.10.2.10 Incompressible material

IncompressibleMaterial is an incompressible isotropic material that implements pure incompressibility, with an energy density function given by

| (6.29) |

Because it responds only to dilational strains, it must be used in conjunction with another material to resist deviatoric strains. In this context, it can be used to provide dilational support to deviatoric-only materials such as the FullBlemkerMuscle (Section 6.10.3.3).

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| bulkModulus | bulk modulus for incompressibility | 100000 | ✓ | |

| bulkPotential | incompressibility potential function |

QUADRATIC |

IncompressibleMaterials can be created with the following constructors:

| IncompressibleMaterial() |

Create with default values. |

| IncompressibleMaterial (double kappa) |

Create with specified |

6.10.3 Muscle materials

Muscle materials are used to exert stress along a particular direction within a material. This stress may contain both an active component, which depends on the muscle excitation, and a passive component, which depends solely on the stretch along the prescribed direction. Because most muscle materials act only along one direction, they are typically deployed within an FEM as additional materials that act in addition to an underlying material. This can be done using either muscle bundles within a FemMuscleModel (Section 6.9.1.1) or material bundles within any FEM model (Sections 6.8 and 7.5.2).

All of the muscle materials described below assume (near)

incompressibility, and so the directional stress is a function of the

deviatoric stretch ![]() along the muscle direction instead of the

overall stretch

along the muscle direction instead of the

overall stretch ![]() . The former can be determined from the

latter via

. The former can be determined from the

latter via

| (6.29) |

where ![]() is the determinant of the deformation gradient. The

directional Cauchy stress

is the determinant of the deformation gradient. The

directional Cauchy stress ![]() resulting from the material is

computed from

resulting from the material is

computed from

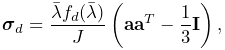

|

(6.30) |

where ![]() is a force term,

is a force term, ![]() is a unit vector indicating

the current muscle direction in spatial coordinates, and

is a unit vector indicating

the current muscle direction in spatial coordinates, and ![]() is the

is the ![]() identity matrix. In a purely passive case when the force arises

from a stress energy density function

identity matrix. In a purely passive case when the force arises

from a stress energy density function ![]() , we have

, we have

| (6.31) |

The muscle direction is specified in one of two ways, depending on how

the muscle material is deployed. All muscle materials export a

property restDir which specifies the direction in material

(rest) coordinates. It has a default value of ![]() , and can

be either set explicitly or bound to a field to allow it to vary over the

entire model (Section 7.5.2). However, if a muscle

material is deployed within a muscle bundle

(Section 6.9.1), then the restDir property is

ignored and the direction is instead specified by the

MuscleElementDesc components contained

within the bundle (Section 6.9.3).

, and can

be either set explicitly or bound to a field to allow it to vary over the

entire model (Section 7.5.2). However, if a muscle

material is deployed within a muscle bundle

(Section 6.9.1), then the restDir property is

ignored and the direction is instead specified by the

MuscleElementDesc components contained

within the bundle (Section 6.9.3).

Likewise, muscle excitation is specified using the material’s excitation property, unless the material is deployed within a muscle bundle, in which case it is controlled by the excitation property of the bundle.

6.10.3.1 Generic muscle

GenericMuscle

is a muscle material whose force term ![]() is given by

is given by

| (6.32) |

where ![]() is the excitation signal,

is the excitation signal, ![]() is a maximum stress

term, and

is a maximum stress

term, and ![]() is a passive force given by

is a passive force given by

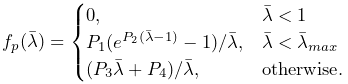

|

(6.33) |

In the equation above, ![]() is the exponential stress coefficient,

is the exponential stress coefficient,

![]() is the uncrimping factor, and

is the uncrimping factor, and ![]() and

and ![]() are computed to

provide

are computed to

provide ![]() continuity at

continuity at ![]() .

.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| maxStress | maximum stress | 30000 | ✓ | |

| maxLambda |

|

1.4 | ✓ | |

| expStressCoeff | exponential stress coefficient | 0.05 | ✓ | |

| uncrimpingFactor | uncrimping factor | 6.6 | ✓ | |

| restDir | direction in material coordinates | ✓ | ||

| excitation | activation signal | 0 |

GenericMuscles can be created with the following constructors:

| GenericMuscle() |

Create with default values. |

| GenericMuscle (double maxLambda, double maxStress, Mdouble expStressCoef, double uncrimpFactor) |

Create with specified |

The constructors do not specify restDir. If the material is not being deployed within a muscle bundle, then restDir should also be set appropriately, either directly or via a field (Section 7.5.2).

6.10.3.2 Blemker muscle

BlemkerMuscle

is a muscle material implementing the directional component of the

model proposed by Sylvia Blemker [5]. Its force

term ![]() is given by

is given by

| (6.33) |

where ![]() is a maximum stress term,

is a maximum stress term, ![]() is the excitation

signal,

is the excitation

signal, ![]() is an active force-length curve, and

is an active force-length curve, and ![]() is

the passive force.

is

the passive force. ![]() and

and ![]() are described in

terms of

are described in

terms of ![]() :

:

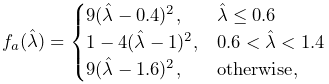

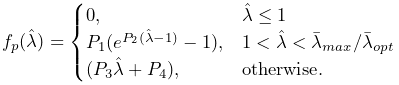

|

(6.34) |

and

|

(6.35) |

In the equation for ![]() ,

, ![]() is the exponential stress

coefficient,

is the exponential stress

coefficient, ![]() is the uncrimping factor, and

is the uncrimping factor, and ![]() and

and ![]() are

computed to provide

are

computed to provide ![]() continuity at

continuity at ![]() .

.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| maxStress | maximum stress | 300000 | ✓ | |

| optLambda |

|

1 | ✓ | |

| maxLambda |

|

1.4 | ✓ | |

| expStressCoeff | exponential stress coefficient | 0.05 | ✓ | |

| uncrimpingFactor | uncrimping factor | 6.6 | ✓ | |

| restDir | direction in material coordinates | ✓ | ||

| excitation | activation signal | 0 |

BlemkerMuscles can be created with the following constructors:

| BlemkerMuscle() |

Create with default values. |

| BlemkerMuscle (double maxLam, double optLam, Mdouble maxStress, double expStressCoef, double uncrimpFactor) |

Create with specified |

The constructors do not specify restDir. If the material is not being deployed within a muscle bundle, then restDir should also be set appropriately, either directly or via a field (Section 7.5.2).

6.10.3.3 Full Blemker muscle

FullBlemkerMuscle

is a muscle material implementing the entire model proposed by Sylvia

Blemker [5]. This includes the directional

stress described in Section 6.10.3.2, plus additional

passive terms to model the tissue material matrix. The latter is based

on a strain energy density function ![]() given by

given by

| (6.35) |

where ![]() and

and ![]() are the along-fibre and cross-fibre

shear moduli, respectively, and

are the along-fibre and cross-fibre

shear moduli, respectively, and ![]() and

and ![]() are

Criscione invariants. The latter are defined as follows: Let

are

Criscione invariants. The latter are defined as follows: Let ![]() and

and ![]() be the invariants of the deviatoric left Cauchy

Green tensor

be the invariants of the deviatoric left Cauchy

Green tensor ![]() ,

, ![]() the unit vector giving the current muscle

direction in spatial coordinates, and

the unit vector giving the current muscle

direction in spatial coordinates, and ![]() and

and ![]() additional invariants defined by

additional invariants defined by

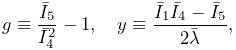

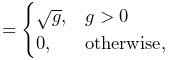

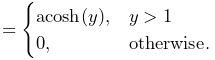

| (6.36) |

Then, defining

|

![]() and

and ![]() are given by

are given by

|

(6.37) | |||

|

(6.38) |

At present, FullBlemkerMuscle does not implement a volumetric potential function

. That means it responds solely to deviatoric strains, and so if it is being used as a model’s primary material, it should be augmented with an additional material to provide resistance to compression. A simple choice for this is the purely incompressible material IncompressibleMaterial, described in Section 6.10.2.10.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| maxStress | maximum stress | 300000 | ✓ | |

| optLambda |

|

1 | ✓ | |

| maxLambda |

|

1.4 | ✓ | |

| expStressCoeff | exponential stress coefficient | 0.05 | ✓ | |

| uncrimpingFactor | uncrimping factor | 6.6 | ✓ | |

| G1 | along-fibre shear modulus | 0 | ✓ | |

| G2 | cross-fibre shear modulus | 0 | ✓ | |

| restDir | direction in material coordinates | ✓ | ||

| excitation | activation signal | 0 |

FullBlemkerMuscles can be created with the following constructors:

| FullBlemkerMuscle() |

Create with default values. |

| BlemkerMuscle (double maxLam, double optLam, Mdouble maxStress, double expStressCoef, Mdouble uncrimpFactor, double G1, double G2) |

Create with |

The constructors do not specify restDir. If the material is not being deployed within a muscle bundle, then restDir should also be set appropriately, either directly or via a field (Section 7.5.2).

6.10.3.4 Simple force muscle

SimpleForceMuscle

is a very simple muscle material whose force term ![]() is

given by

is

given by

| (6.39) |

where ![]() is the excitation signal and

is the excitation signal and ![]() is a maximum

stress term. It can be useful as a debugging tool.

is a maximum

stress term. It can be useful as a debugging tool.

The material behavior is controlled by the following properties:

| Property | Description | Default | Field | |

|---|---|---|---|---|

| maxStress | maximum stress | 30000 | ✓ | |

| restDir | direction in material coordinates | ✓ | ||

| excitation | activation signal | 0 |

SimpleForceMuscles can be created with the following constructors:

| SimpleForceMuscle() |

Create with default values. |

| SimpleForceMuscle (double maxStress) |

Create with specified |

The constructors do not specify restDir. If the material is not being deployed within a muscle bundle, then restDir should also be set appropriately, either directly or via a field (Section 7.5.2).